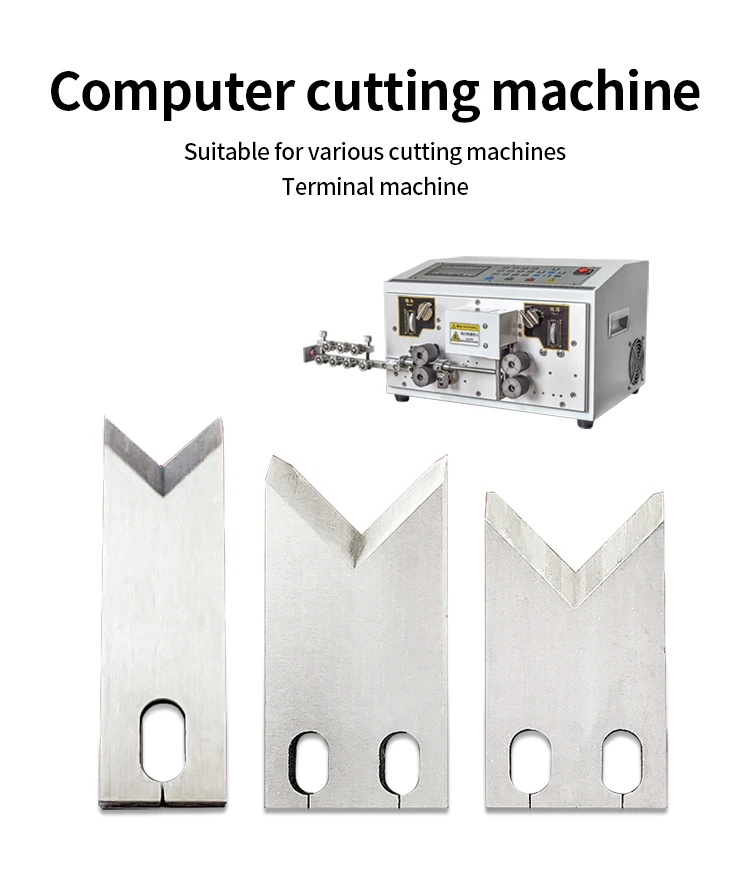

High-Speed Steel Blade OTP Computer Wire Cutting & Stripping Machine: Precision and Efficiency for Modern Wiring Needs

In today’s rapidly evolving technological landscape, the demand for efficient and precise wire processing has become paramount across various industries. From the intricate wiring of computer systems to the complex harnesses found in automotive electronics, the need for reliable and high-speed wire preparation is constantly growing. This report details the capabilities and benefits of the High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine, a cutting-edge solution designed to streamline wire processing workflows and enhance productivity 1.

I. Superior Performance with High-Speed Steel Blade Technology

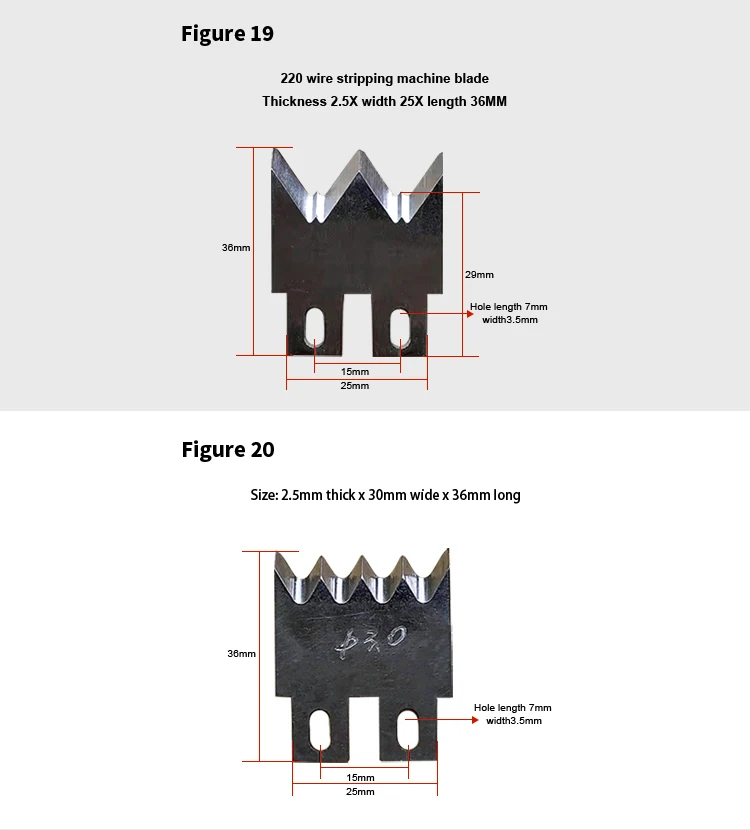

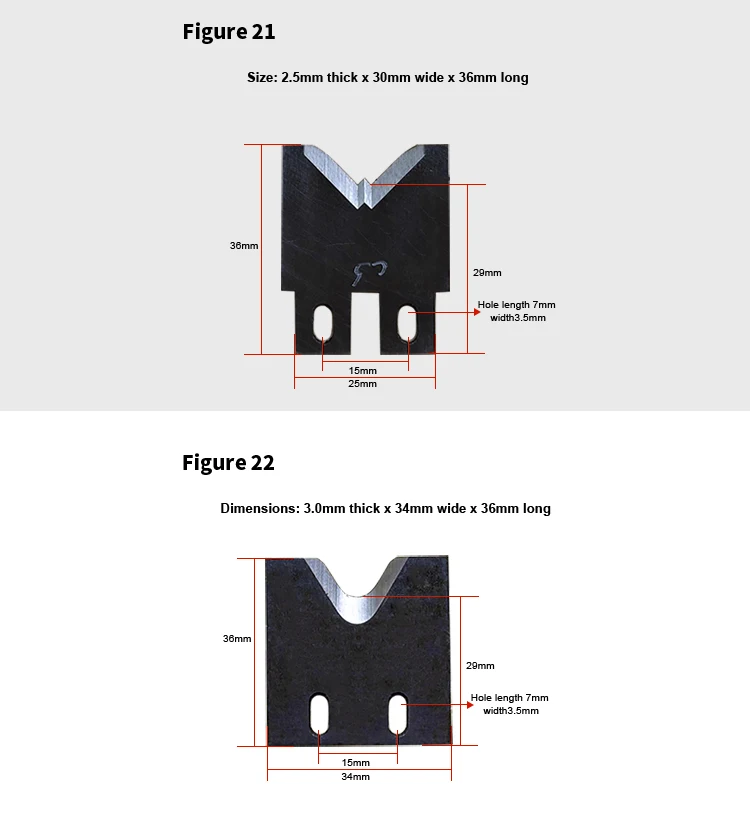

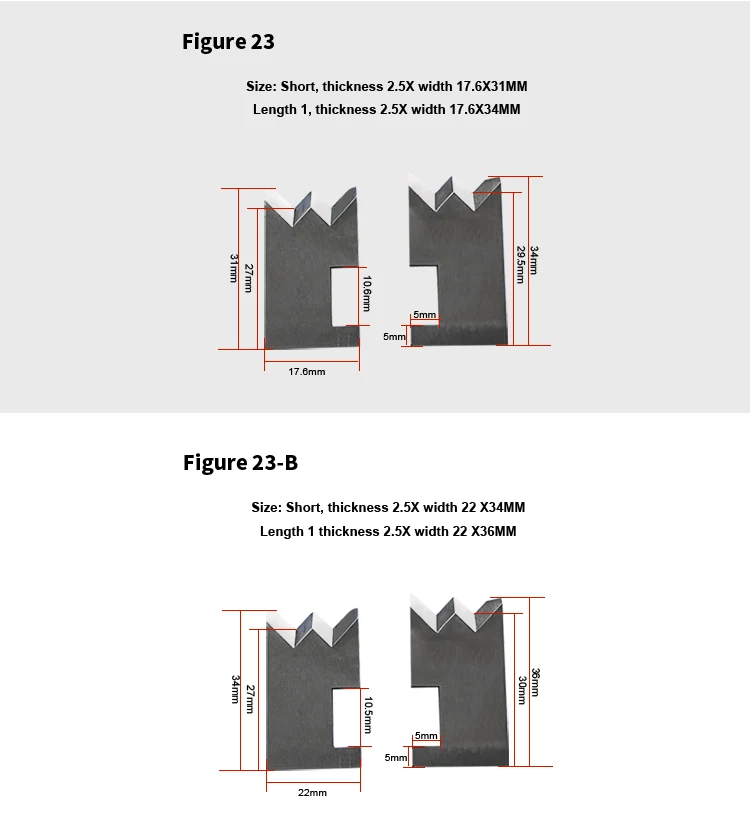

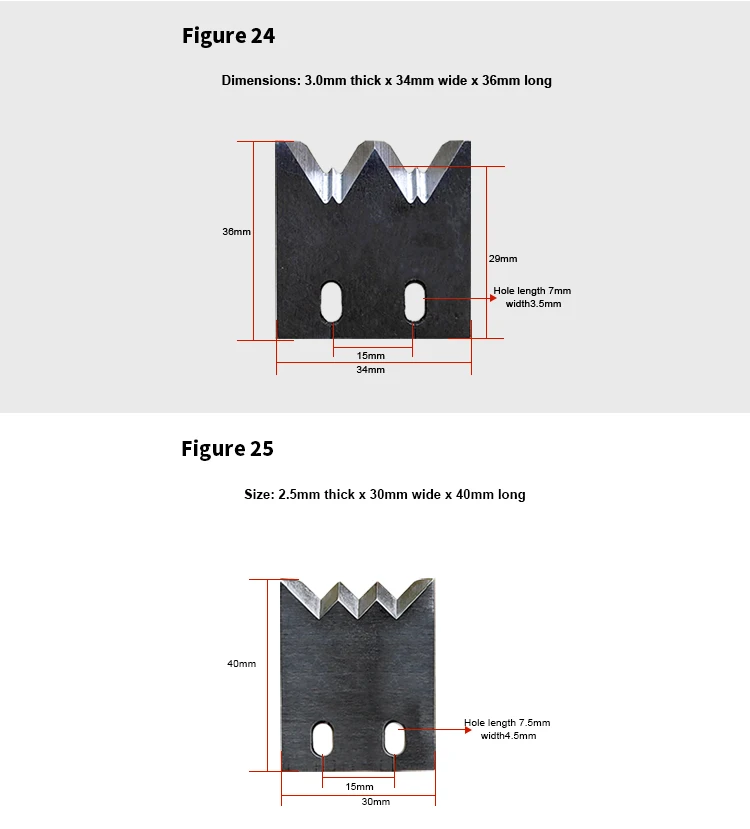

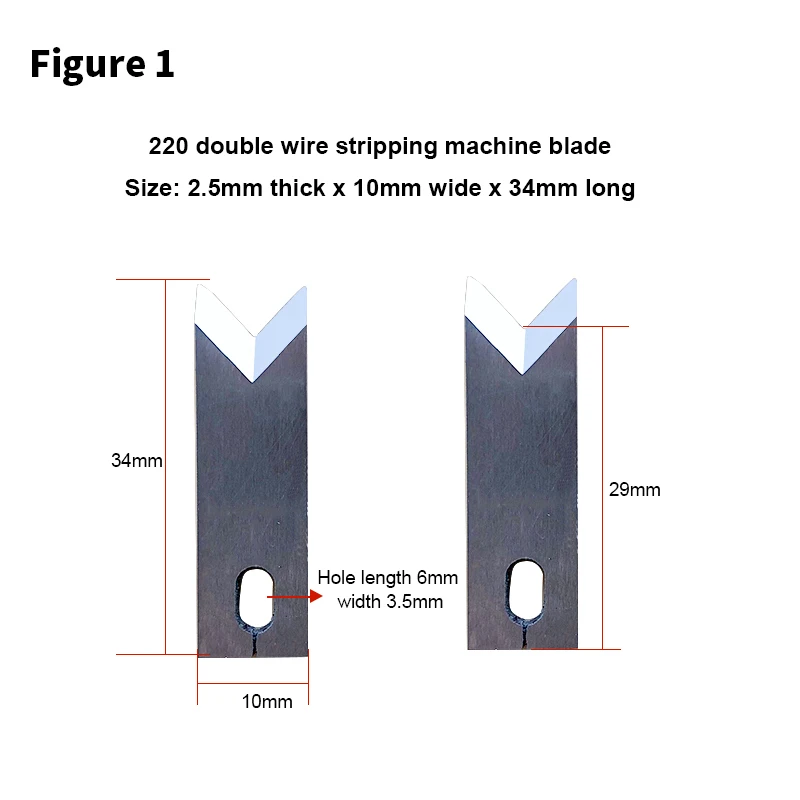

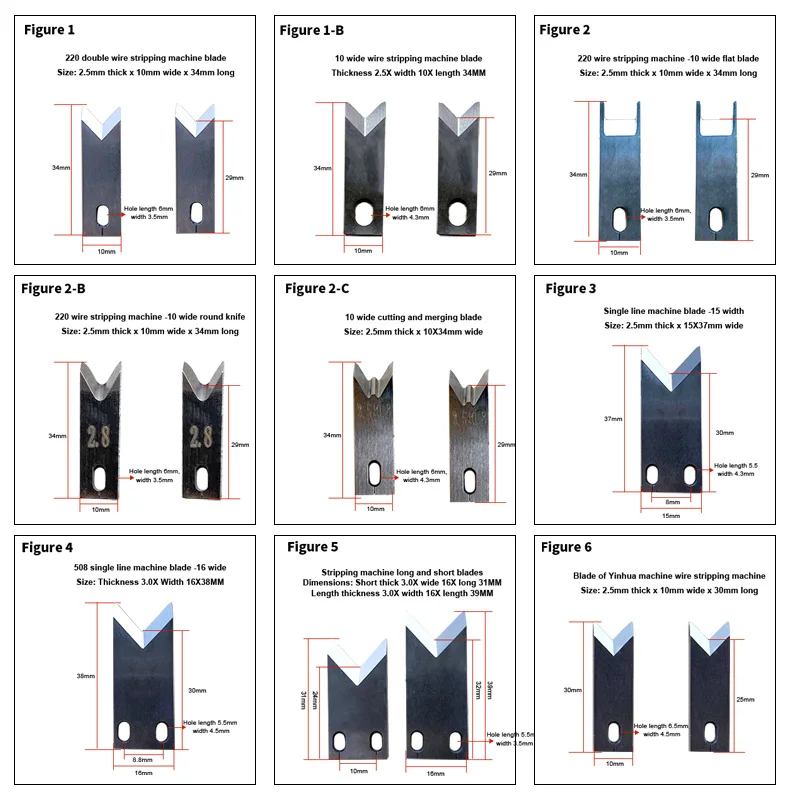

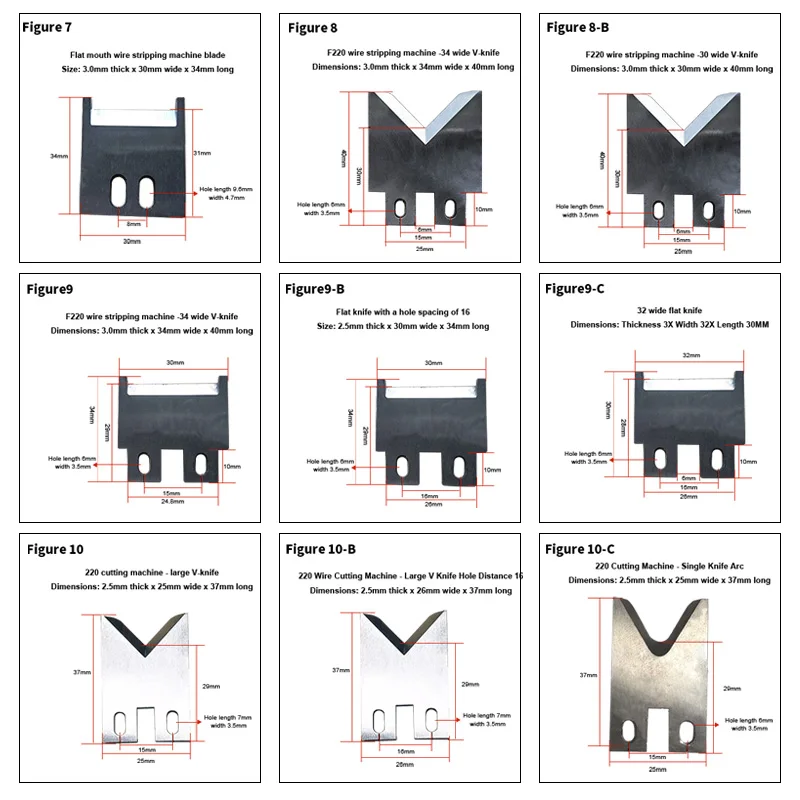

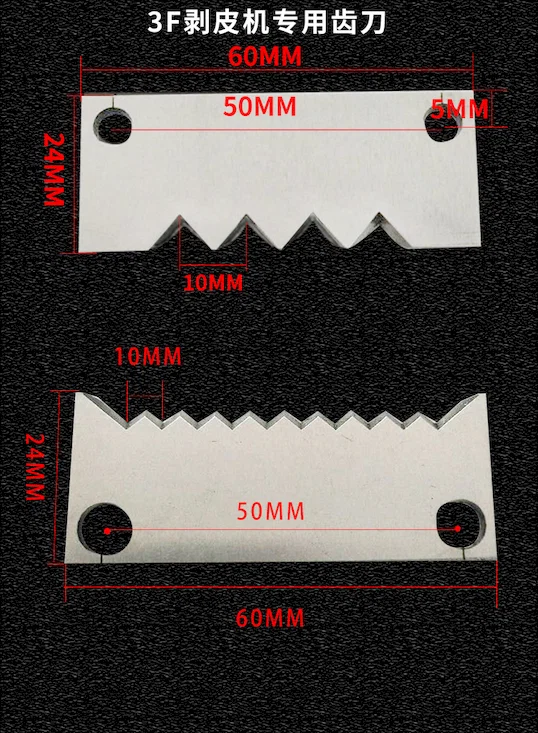

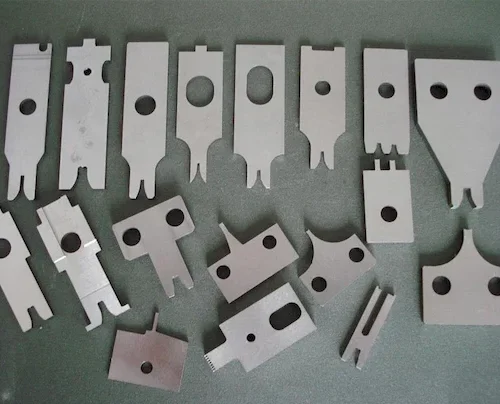

At the heart of this advanced machine lies its premium high-speed steel blade 1. This critical component ensures sharp, clean, and durable cuts on a consistent basis, even under the demands of frequent use 1. Unlike standard blades, high-speed steel offers exceptional resistance to wear and tear, significantly reducing the need for frequent replacements and guaranteeing sustained high performance over extended periods 1. This durability translates to lower operational costs and increased uptime for businesses relying on efficient wire processing. The precision offered by these blades also minimizes the risk of damage to the wire’s core, ensuring the integrity and reliability of the final product.

II. Automated Precision for Cutting, Stripping, Peeling, and Terminal Processing

This machine represents a significant leap forward from manual wire processing methods by automating the critical steps of cutting, stripping, peeling, and even handling terminal preparation 1. The integration of these functions into a single unit offers a comprehensive solution for preparing wires for various applications, particularly in the realm of OTP (One-Time Programmable) computer wiring 1. The automatic cutting feature ensures consistent and accurate wire lengths, eliminating the variability often associated with manual cutting. Furthermore, the automated stripping and peeling mechanisms precisely remove insulation without damaging the conductor, a crucial factor for ensuring proper electrical connections. This level of automation not only accelerates the wire preparation process but also significantly reduces the potential for human error, leading to higher quality and more reliable end products.

III. Versatile Compatibility Across a Wide Range of Wire Specifications

The High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine is engineered to handle a broad spectrum of wire types and sizes, making it a versatile asset for diverse applications 1. It can accommodate single-core and multi-core wires, as well as various insulation materials such as PVC, Teflon, silicone cable, and fiberglass wire 3. The machine boasts a wire cross-section processing capability ranging from 0.1 to 4.5 mm², which corresponds to AWG (American Wire Gauge) sizes from #12 to #32 2. This wide range ensures compatibility with many common wire sizes used in computer wiring and electronics. Additionally, the machine can handle a maximum outer diameter of ¢ 7 mm 2, further demonstrating its ability to process a variety of wire and cable types. This extensive compatibility reduces the need for multiple specialized machines, providing a comprehensive solution for various wire processing needs.

IV. Robust Construction and Protective Design for Longevity and Safety

Built with heavy-duty materials, such as the solid aluminum alloy mentioned in similar models, this wire stripping machine is designed to withstand the rigors of industrial environments and endure years of demanding use 2. This robust construction ensures the machine’s stability during operation and contributes to its overall longevity, representing a sound long-term investment. Furthermore, safety is a paramount consideration in the design. Features like a protective shell and screw nuts with high stiffness and hardness provide essential protection for both the internal components, particularly the delicate blades, and the operator 2. This protective design minimizes the risk of accidents and ensures a safe working environment.

V. High Stripping Speed and Efficiency for Enhanced Productivity

The machine is engineered to deliver a fast stripping speed, significantly improving working efficiency and overall productivity 2. While the exact stripping speed for this specific model may vary, comparable machines can achieve speeds of 3000 to 8000 pieces per hour for a 100 mm length wire 3. This high throughput allows businesses to process large volumes of wires quickly, meeting tight production deadlines and increasing their overall output capacity. The ability to rapidly prepare wires for subsequent processes like terminal crimping or tin plating translates directly to reduced processing time per unit and enhanced operational efficiency.

VI. Broad Applicability Across Diverse Industries

The versatility and efficiency of this automatic wire stripping machine make it an invaluable tool across a wide range of industries and applications 2. These include:

- Manufacturing of computer components and peripherals: Precisely preparing wires for motherboards, CPUs, memory modules, and other critical components.

- Production of electronic devices and assemblies: Efficiently processing wires for televisions, audio equipment, gaming consoles, and various other electronic goods.

- Wiring for electrical appliances and consumer electronics: Ensuring accurate and reliable wire preparation for household appliances and other electronic products.

- Automotive wiring harness manufacturing: Contributing to the efficient production of complex wiring systems for vehicles.

- Telecommunications equipment assembly: Preparing wires for network cables, communication systems, and data transmission infrastructure.

- Research and development laboratories: Providing a precise and efficient tool for prototyping and experimentation involving computer and electronic wiring.

This extensive range of applications underscores the machine’s adaptability and its potential to benefit various sectors requiring precise and efficient wire processing.

VII. Integrated Cooling System for Sustained Performance

The inclusion of a powerful cooling system, often featuring a large fan, plays a crucial role in maintaining the machine’s performance and longevity 2. This system effectively dissipates heat generated by the motor and other internal components during operation. By preventing overheating, the cooling system ensures consistent performance even during prolonged periods of use. This is particularly important in high-demand production environments where the machine may operate continuously for extended durations. Furthermore, effective heat dissipation helps to protect critical components from thermal damage, extending their lifespan and reducing the likelihood of costly repairs or downtime.

VIII. User-Friendly Operation and Programmable Settings

Equipped with a professional LCD panel and microcomputer control, this automatic wire stripping machine offers a user-friendly interface for easy operation and programming 2. The availability of 0 to 99 programmable settings allows users to customize the machine’s parameters to meet specific stripping needs, such as full strip, half strip, middle strip, and ultra-thin wire processing 2. The intuitive controls and clear display make it easy for operators to set cutting lengths, stripping lengths, and other parameters with precision. This ease of use minimizes the learning curve and allows for quick setup and adjustments, contributing to increased efficiency and flexibility in wire processing tasks.

IX. Technical Specifications: Performance at a Glance

The following table provides a summary of the key technical specifications for the High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine:

| Specification | Value |

| Power Supply | AC 200W 2 |

| Motor Power | 200 W 2 |

| Cutting Length Range | 1-9999 mm / 0.04 – 393.7 in 2 |

| Cutting Tolerance | (0.2 ± 0.002 x L) mm 2 |

| Stripping Length Range (Head) | 0-35 mm 2 |

| Stripping Length Range (End) | 0-15 mm 2 |

| Intermediate Stripping Cut | 11 Department Stripping 2 |

| Wire Cross-Section Range | 0.1-4.5 mm² (AWG12 #-AWG32 #) 2 |

| Max. Catheter Diameter | ¢ 7 2 |

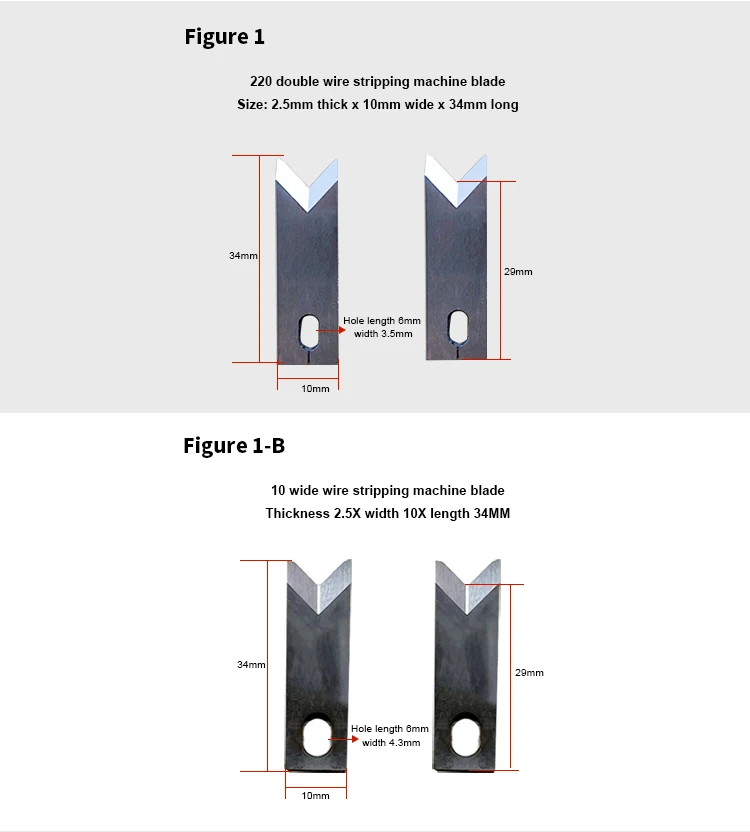

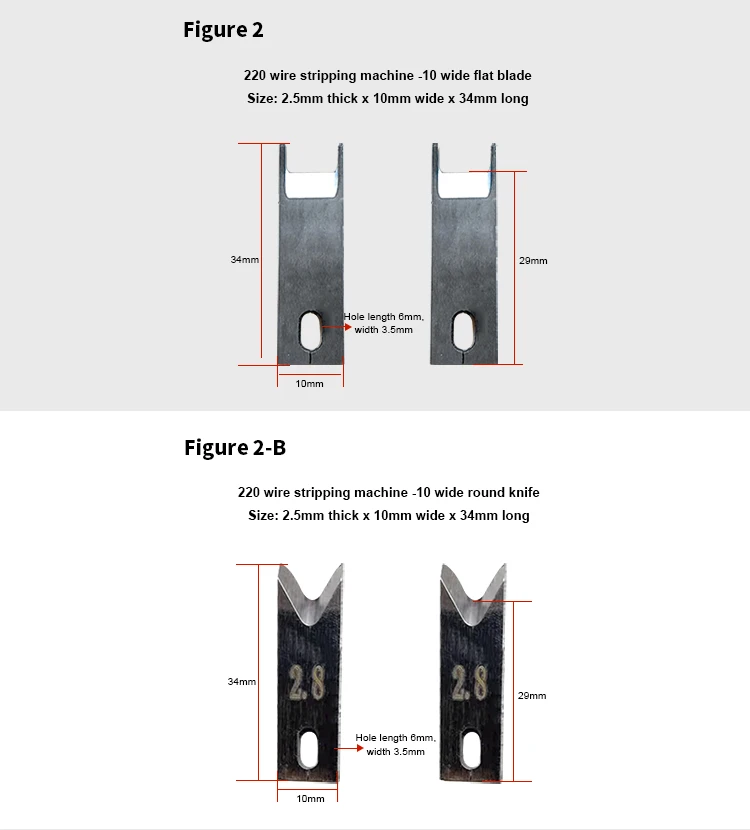

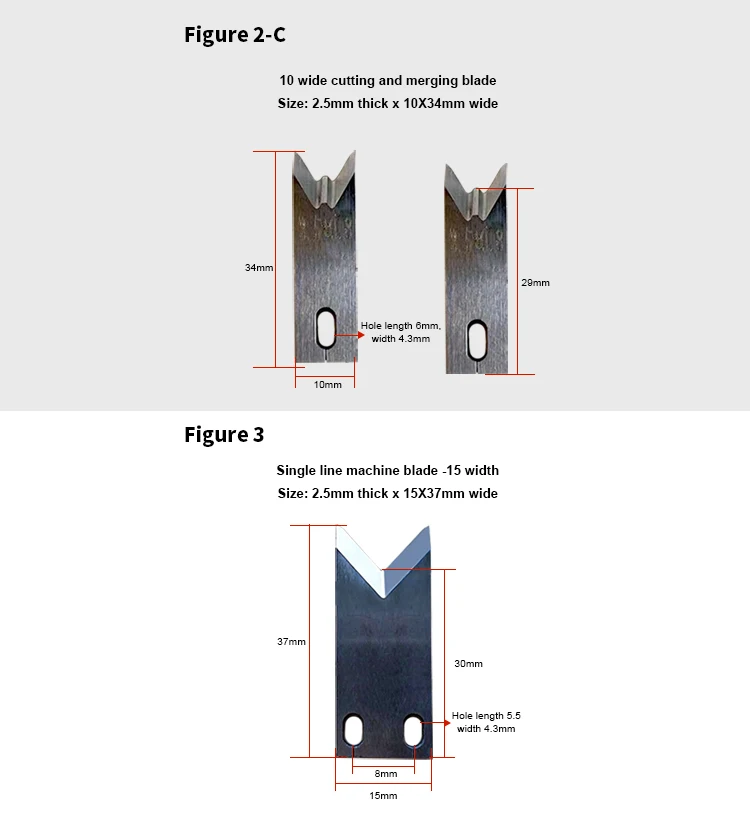

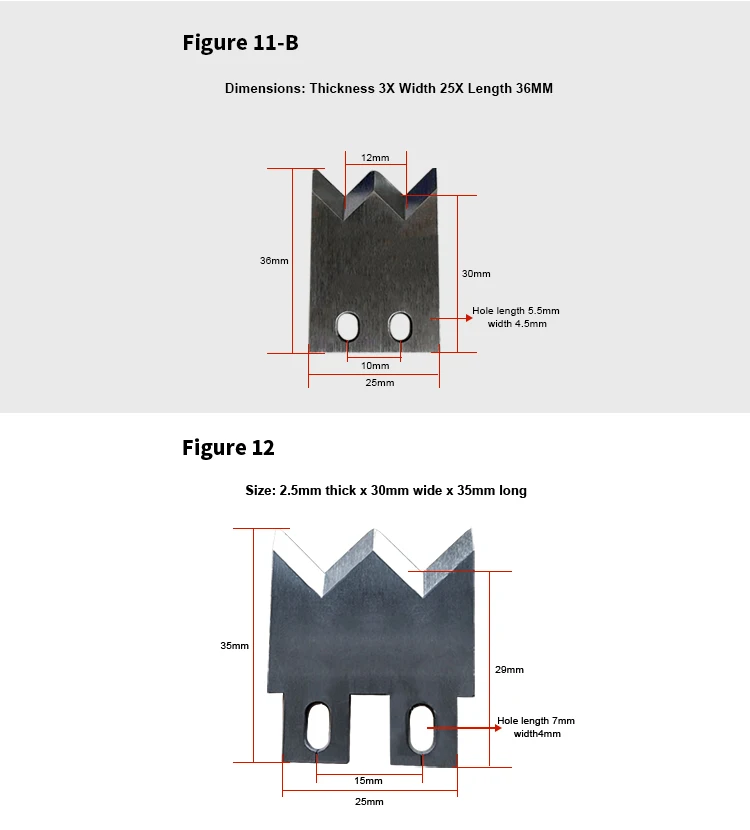

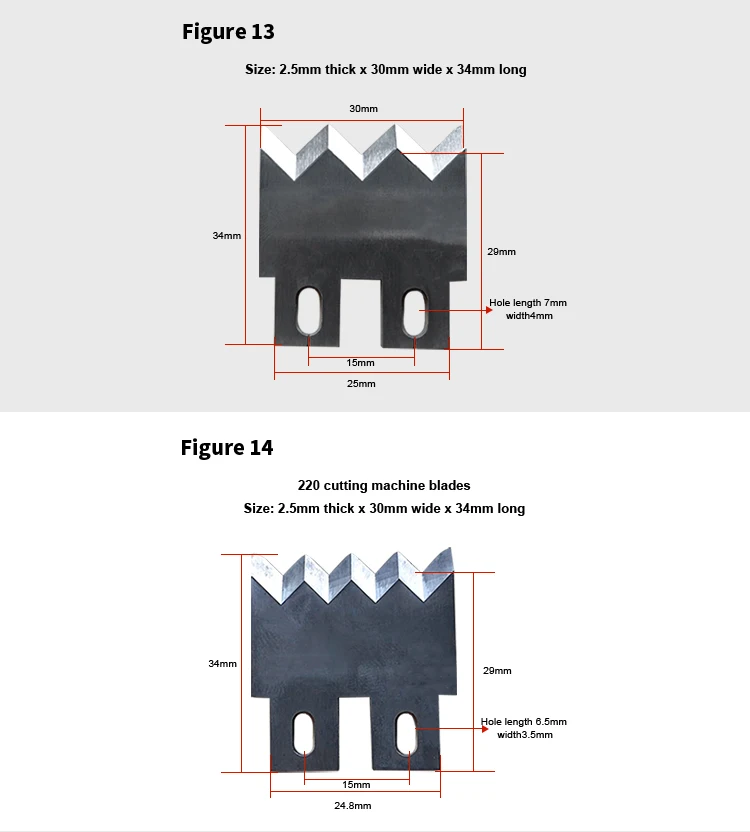

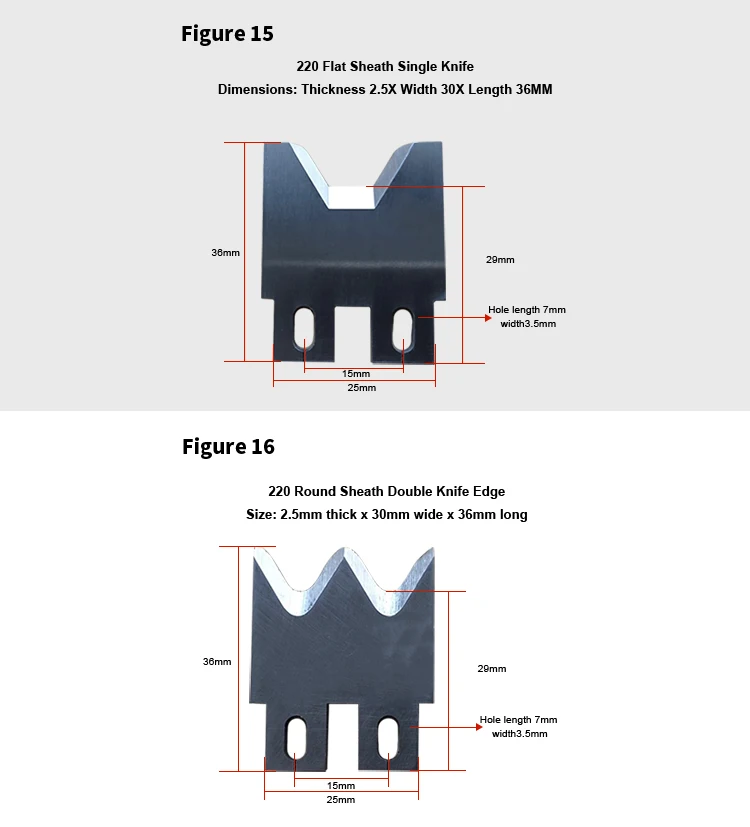

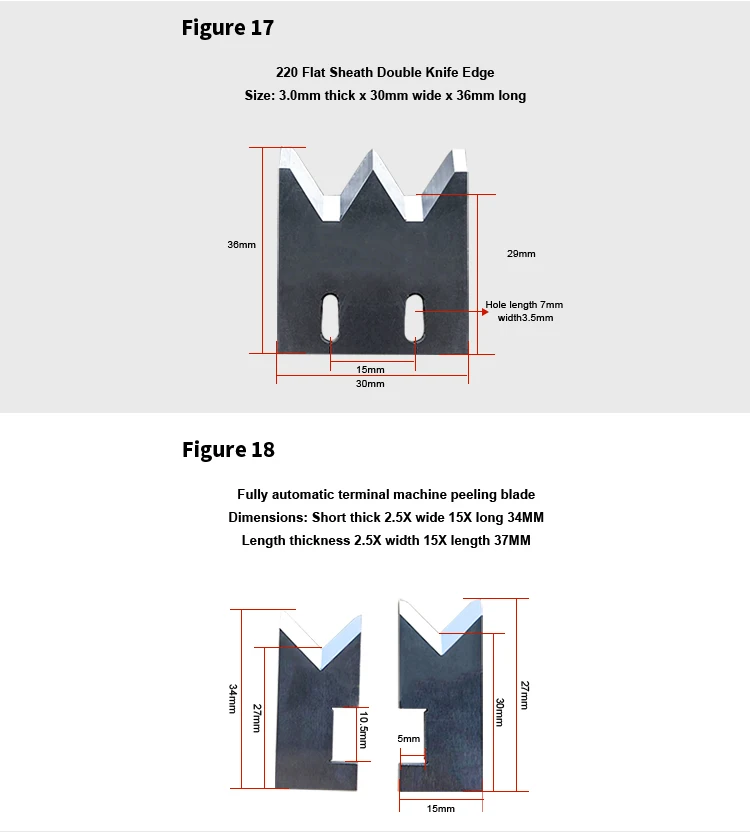

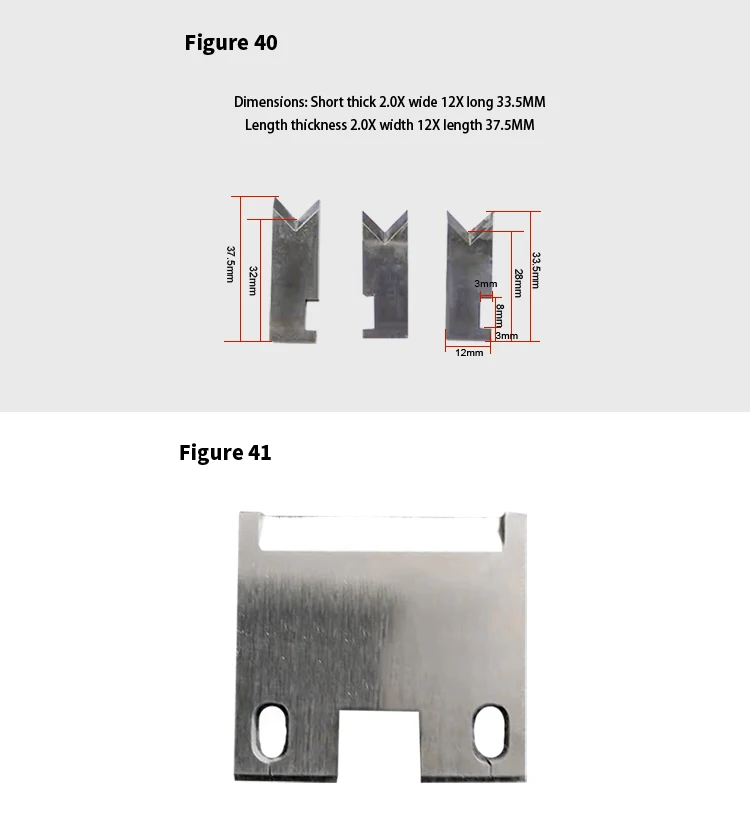

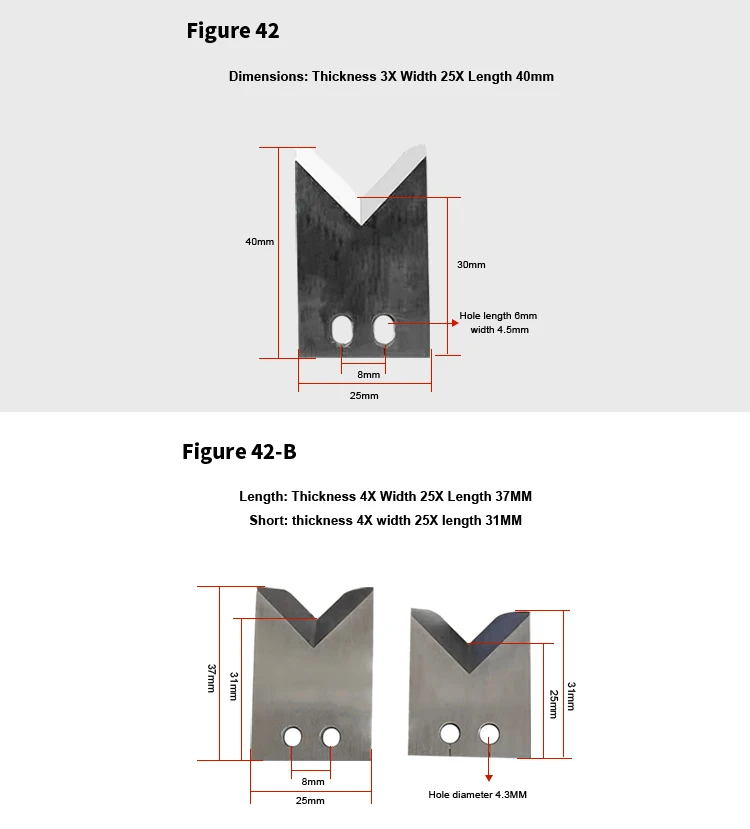

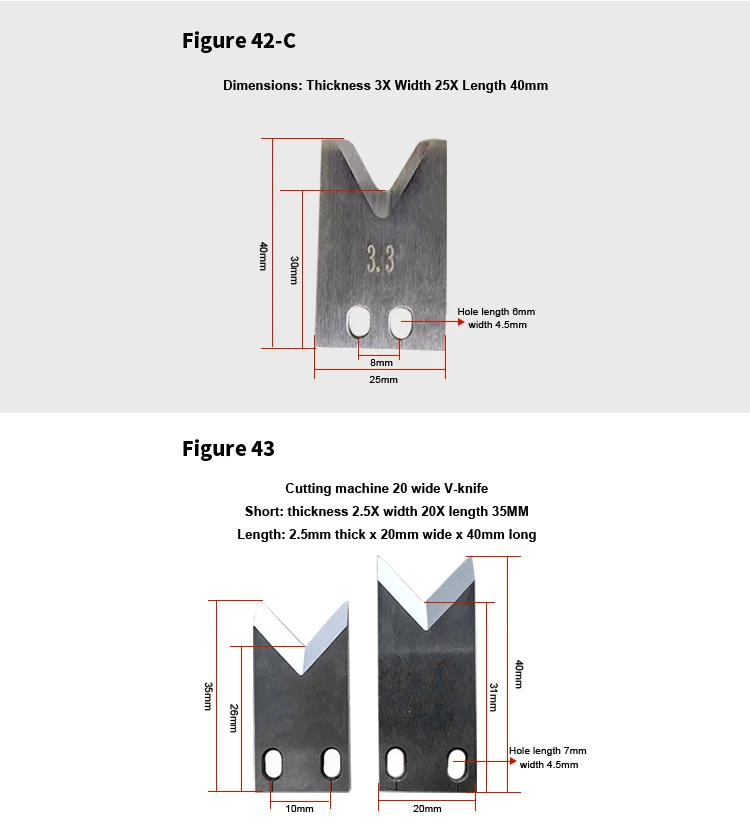

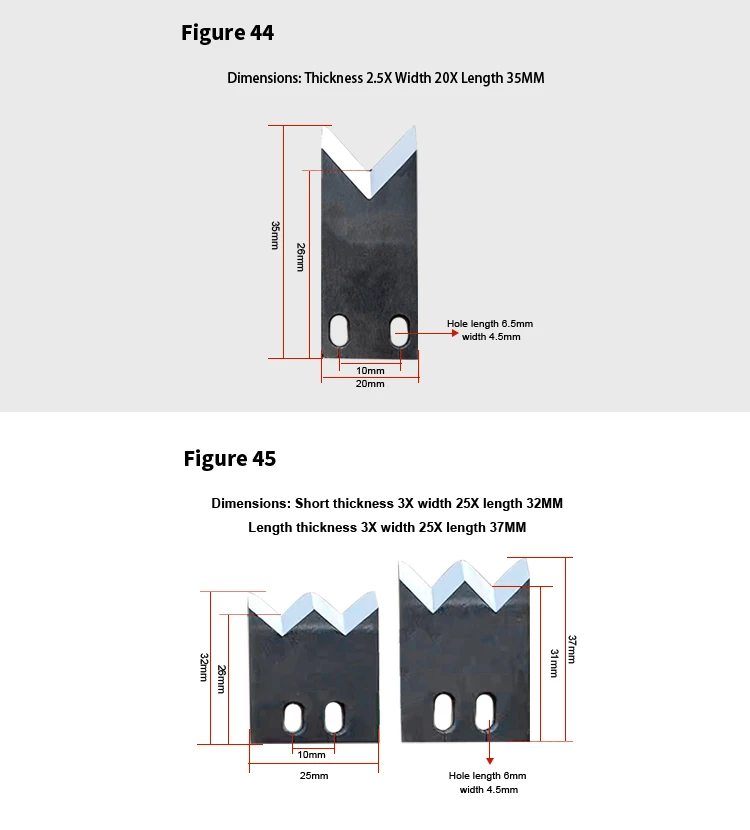

| Blade Material | High Hardness Blades 2 |

| Display | English LCD Interface 2 |

| Number of Programmable Settings | 0-99 Programs 2 |

This table provides essential information for potential buyers to quickly assess if the machine meets their specific technical requirements.

X. Applications: Versatility in Action

This automatic wire stripping machine is ideally suited for a wide array of applications, including:

- Computer and IT Hardware Manufacturing

- Consumer Electronics Production

- Telecommunications Industry

- Industrial Automation

- Automotive Electronics

- Research and Development

- Repair and Maintenance Services

Its ability to handle OTP computer wire and perform automatic cutting, terminal peeling, and tin-coated wire preparation makes it particularly valuable in these sectors.

XI. Why Invest in This Automatic Wire Stripping Machine?

Choosing this High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine offers numerous compelling advantages:

- Maximize Productivity: Achieve significantly faster wire processing speeds compared to manual methods, leading to higher production volumes and quicker turnaround times.

- Ensure Precision and Accuracy: Benefit from consistent and accurate cutting and stripping lengths, minimizing errors, reducing material waste, and ensuring high-quality wire preparation for reliable connections.

- Enhance Operational Efficiency: Automate a labor-intensive task, freeing up valuable human resources for other critical operations and reducing overall labor costs.

- Versatile Application: Process a wide range of wire types and sizes, including the specific needs of OTP computer wire, making it a flexible and adaptable solution for various projects.

- Durable and Reliable Performance: The high-speed steel blade and robust construction ensure long-lasting and dependable operation, minimizing downtime and maintenance requirements.

- User-Friendly Operation and Programming: The intuitive LCD interface and programmable settings make it easy to set up and operate, even for users with limited prior experience.

Investing in this machine translates to a significant improvement in wire processing efficiency, accuracy, and overall productivity.

XII. Package Contents: What You Will Receive

The standard package for the High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine typically includes:

- 1 x Automatic OTP Computer Wire Cutting & Stripping Machine

- 1 x High-Speed Steel Blade (Installed)

- 1 x Sensor 2

- 2 x Alternate Catheters 2

- 2 x Blades 2

- 2 x Straightener Pads 2

- 3 x Allen Keys 2

- 3 x Fuses 2

- 1 x Wire Straightener 5

- 1 x Collection Plate 5

- 1 x Manual 5

Please refer to the specific product listing for the definitive list of included items.

XIII. SEO Optimization and Keywords

To ensure maximum visibility and reach potential customers, this product description incorporates relevant keywords such as: OTP Computer Wire Cut Machine, High-Speed Steel Blade Wire Stripping Machine, Automatic Cutting Terminal Peeling, Tin Coated Wire Preparation, Automatic Wire Stripper, Computer Wire Processing, Wire Cutting Machine, Wire Peeling Machine, Programmable Wire Stripper, Industrial Wire Stripping Machine. These keywords are strategically placed throughout the text to improve search engine rankings and attract qualified buyers.

XIV. Call to Action

Upgrade your wire processing capabilities with the High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine. Experience the benefits of increased efficiency, precision, and reliability. Contact us today for a quote or to learn more!

XV. Conclusion

The High-Speed Automatic OTP Computer Wire Cutting & Stripping Machine represents a significant advancement in wire processing technology. Its combination of a durable high-speed steel blade, comprehensive automation of cutting, stripping, peeling, and terminal preparation, and versatile compatibility with a wide range of wire specifications makes it an indispensable tool for industries relying on efficient and precise wire preparation. The robust construction, integrated cooling system, and user-friendly interface further enhance its value proposition, ensuring long-term reliability and ease of operation. By investing in this machine, businesses can significantly improve their productivity, reduce operational costs, and ensure the high quality of their wire processing operations.

Reviews

There are no reviews yet.