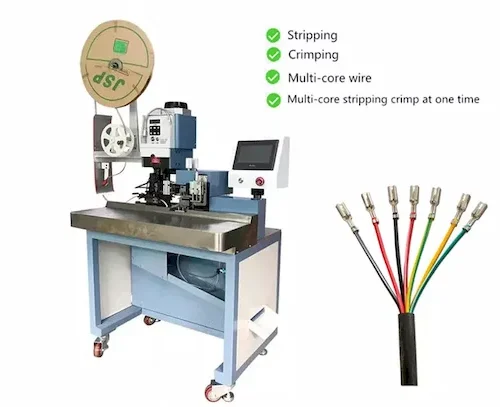

High-Efficiency Semi-Automatic Terminal Wire Crimping Machine for Diverse Wire Processing Needs

Our Semi-Automatic Terminal Crimping Machine is expertly engineered to streamline your wire processing operations, offering unparalleled efficiency and precision for a wide range of applications. This robust and user-friendly machine is the ideal solution for businesses looking to enhance their production capabilities when working with various terminals and wire types.

Unmatched Versatility for Terminals and Wires:

This versatile crimping machine is specifically designed to handle a comprehensive selection of terminals, including:

- Horizontal Strip Terminals: Perfect for common industry standards.

- Molex Terminals: Ensures secure and reliable connections for Molex connectors.

- JST Terminals: Delivers precise crimping for JST connectors.

- DC Terminals: Suitable for a variety of direct current applications.

- AC Terminals: Capable of processing alternating current terminals.

- Single Grain Terminals: Handles individual terminal pieces with ease.

- Connected Terminals: Efficiently crimps linked terminal strips.

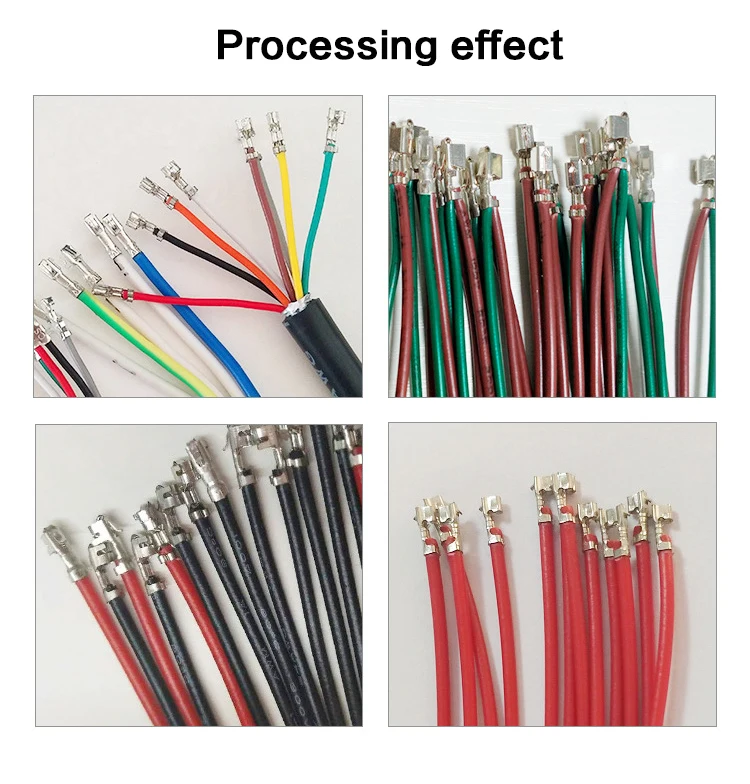

Furthermore, this machine demonstrates exceptional adaptability when processing different wire types, including:

- Electronic Single Wire: Ideal for basic electronic connections.

- Multi-Core Wire: Effectively crimps wires with multiple internal conductors.

- Flat Wire: Designed for flat ribbon cables used in various electronics.

- Computer Core Wire: Suitable for internal wiring within computer systems.

- USB Data Cable: Precisely crimps connectors for USB cables.

- Earphone Cable: Handles the delicate wiring found in earphone and headphone cables.

- Audio Cable: Ensures secure connections for audio signal transmission.

Key Features and Technical Specifications:

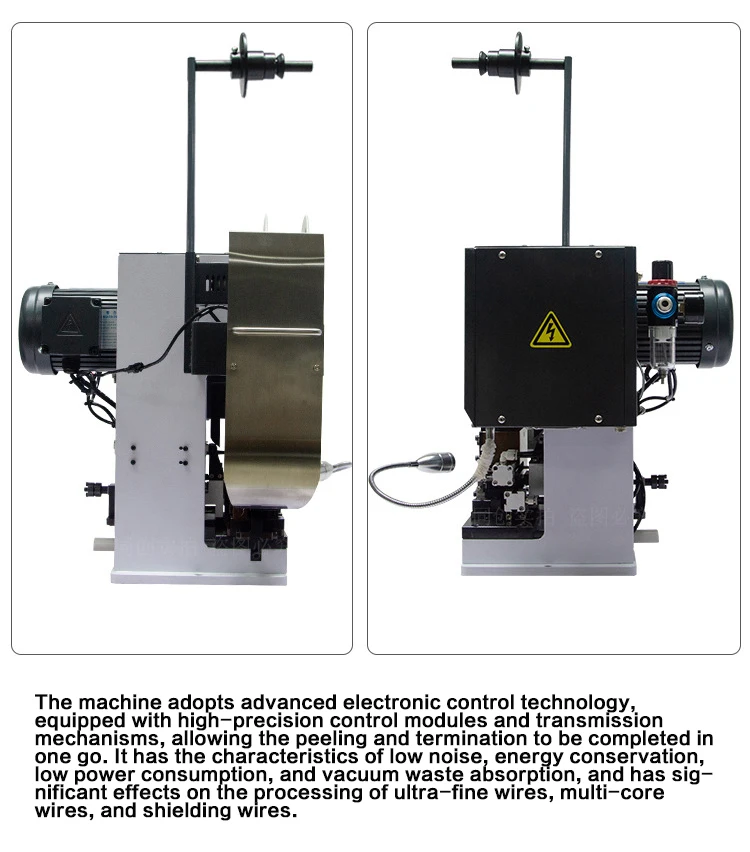

- Horizontal Feeding and Stripping: Facilitates smooth and consistent wire processing.

- Power Supply: Operates on a standard single-phase 200V-240V power supply, making it compatible with most industrial environments.

- Powerful Crimping Force: Delivers a substantial crimping force of 1.8T (1.8 tons), ensuring strong and reliable terminal connections.

- Wide Wire Diameter Range: Accommodates wires with diameters ranging from AWG#36 to AWG#20, offering flexibility for various applications.

- Adjustable Stripping Length: Allows for precise stripping of wire insulation from 1.0mm to 10.0mm.

- Optimal Peeling Stroke: Features a 20mm peeling stroke for efficient insulation removal.

- Air Source Requirement: Requires a clean and dry air source with a pressure of 0.3-0.4Mpa for optimal operation.

- Compact Dimensions: With dimensions of W530mm x L400mm x H830mm, this machine fits comfortably into various workshop layouts.

- Manageable Weight: Weighing in at 70kg, the machine is robust yet relatively easy to maneuver within a workspace.

Benefits of Choosing Our Semi-Automatic Terminal Crimping Machine:

- Increased Efficiency: Automates the terminal crimping process, significantly reducing manual labor and increasing production speed.

- Enhanced Precision: Ensures consistent and accurate crimping results, minimizing errors and waste.

- Improved Reliability: Produces high-quality, secure terminal connections, leading to more reliable finished products.

- User-Friendly Operation: Designed for ease of use, minimizing the learning curve for operators.

- Versatile Applications: Handles a wide variety of terminals and wires, making it a valuable asset for diverse manufacturing needs.

- Durable and Long-Lasting: Built with quality components to ensure long-term reliability and performance.

Ideal for a Range of Industries:

This semi-automatic terminal crimping machine is an essential tool for various industries, including:

- Electronics Manufacturing

- Automotive Wiring Harness Production

- Appliance Manufacturing

- Telecommunications

- Computer and Peripheral Assembly

- Audio and Video Equipment Production

Invest in Efficiency and Precision:

Upgrade your wire processing capabilities with our reliable and efficient Semi-Automatic Terminal Crimping Machine. Experience the benefits of increased productivity, improved accuracy, and reduced operational costs. Contact us today to learn more about how this machine can optimize your production line.

Reviews

There are no reviews yet.