Headline: Automate Cable Management with the WPM-83T: The Ultimate Cable Winding and Tying Machine for Enhanced Productivity

Introduction:

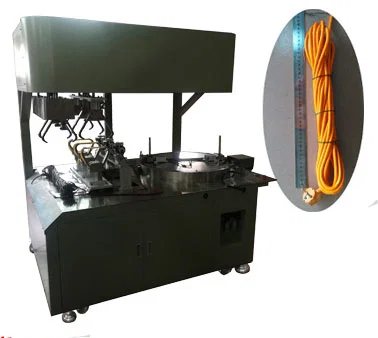

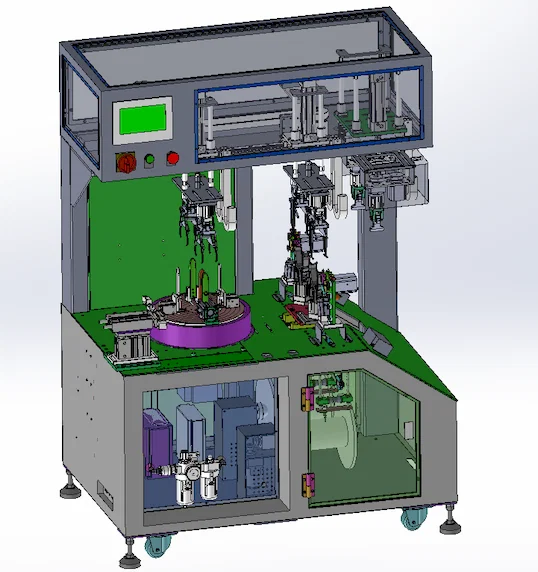

Streamline your cable processing with the WPM-83T Cable Winding Binding Machine, a versatile and efficient solution designed to automate cable winding and tying. This advanced tying machine, also known as a cutting, winding, and tying machine, a cable bunching machine, a cable coiling tying machine, and a cable cutting winding binding machine, is engineered to boost productivity and ensure consistent, high-quality results. Perfect for a range of cable types, the WPM-83T is your all-in-one solution for automated cable management.

Key Features and Benefits:

- Automated Cable Winding and Tying for Increased Efficiency: The WPM-83T automates the entire cable winding and tying process, significantly reducing manual labor and increasing production throughput. This tying machine handles cutting, winding, and double-tying in a single, streamlined operation.

- Circular Shape with Double-Tying for Professional Finish: Achieve a professional and secure cable bundle with the machine’s circular winding shape and double-tying feature. This ensures neat and organized cable management for a polished finished product.

- Versatile Cable Compatibility: This cable bunching machine is designed to handle a variety of cable types, including AC, DC, and USB cables, making it adaptable to diverse production needs.

- Wide Range of Winding Lengths and Diameters: Process cables with outer diameters from 4 to 8 mm and winding lengths from 3 to 20 meters. The adjustable winding speed allows you to optimize the process for different cable types and lengths.

- High Productivity Output: Experience impressive productivity rates, ranging from 250 to 380 pieces per hour (depending on winding length from 3 to 20 meters). The WPM-83T significantly boosts your output compared to manual methods.

- Adjustable Winding Parameters for Customization: The adjustable winding speed and winding part distance (120-220mm) provide flexibility to customize the winding process based on specific cable requirements.

- Pneumatic Operation for Reliable Performance: Utilizing a compressed air connection (0.7 – 0.8 MPa), this cable coiling tying machine ensures reliable and consistent operation with pneumatic precision.

- Compact Footprint and Robust Construction: With dimensions of 1900 × 750 × 1900 mm and a weight of 500 kg, the WPM-83T is designed for industrial environments, offering both a manageable footprint and robust durability for long-term use.

Technical Specifications:

| Feature | Specification |

|---|---|

| Model | WPM – 83T |

| Keyword Focus | tying machine, cable winding binding machine, cable bunching machine, cable coiling tying machine, cable cutting winding binding machine |

| Finished Product Shape | Circular, with double-tying |

| Applicable Cable Types | AC / DC / USB, etc. |

| Wire Outer Diameter | 4 – 8 mm |

| Distance of Winding Part | 120 – 220 mm |

| Winding Length | 3 – 20 m |

| Winding Speed | Adjustable |

| Tying Outer Diameter | ≤ 50 mm |

| Productivity | 250 – 380 pieces per hour (3 – 20 m winding length) |

| Compressed Air Connection | 0.7 – 0.8 MPa |

| Power Supply | 110 V, 220 V (50 – 60 Hz) |

| Power | 3.5 kW |

| Dimension | 1900 × 750 × 1900 mm |

| Weight | 500 kg |

Reviews

There are no reviews yet.