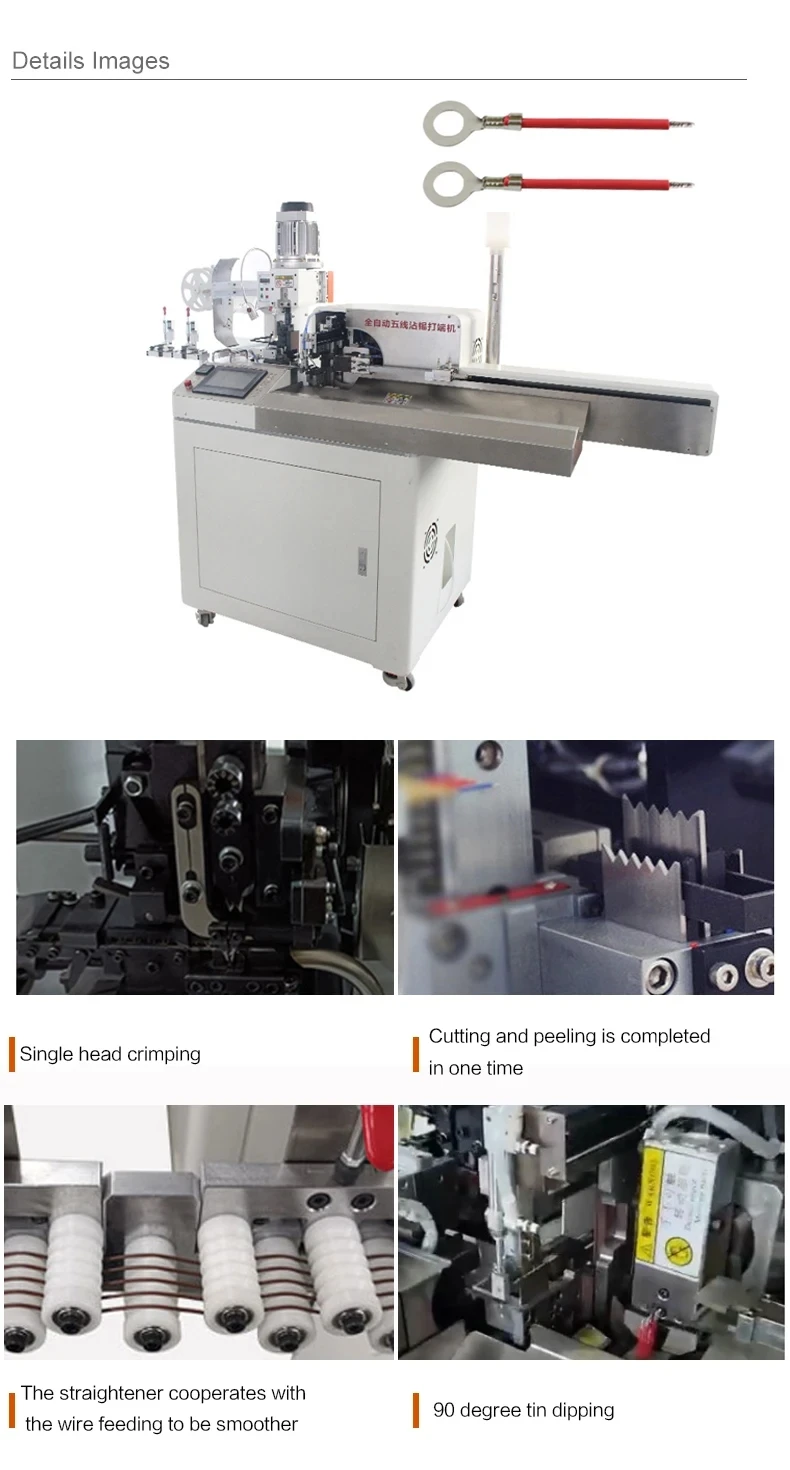

Fully Automatic 5-Wire Cutting Stripping Crimping Tinning Machine WPM-C01

Product Overview:

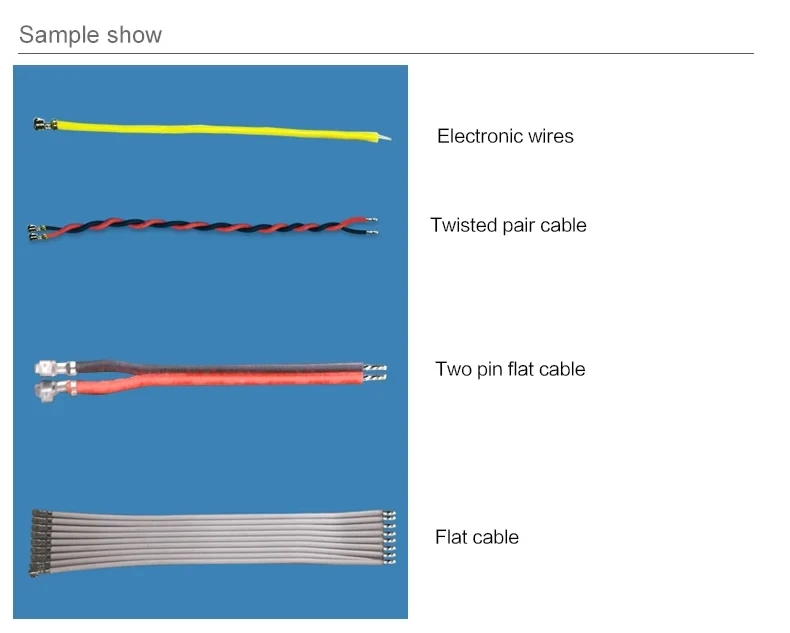

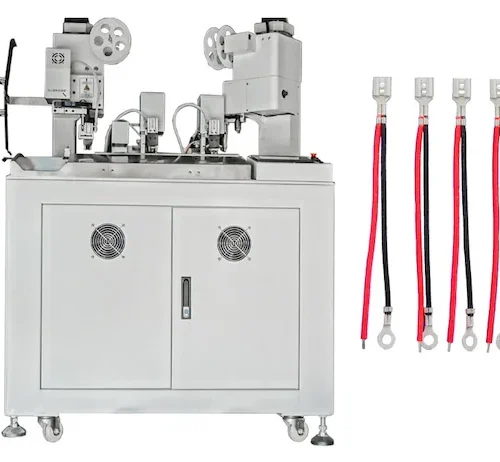

The WPM-C01 is a highly efficient and versatile fully automatic machine designed for processing multi-core wires with precision and speed. This single-head machine integrates five essential wire processing functions: cutting, stripping, crimping, dipping, and tinning, along with a twisting wire capability, streamlining your production line and ensuring consistent, high-quality results. Manufactured in Mainland China and customizable to meet specific needs, the PH-C01 is engineered for reliability and ease of use in demanding industrial environments. This machine does not contain any high-concerned chemicals, ensuring a safer operational setting.

Key Features and Benefits:

- Five-in-One Functionality: Combines cutting, stripping, crimping, dipping, and tinning processes into a single, automated operation, maximizing efficiency and minimizing manual handling.

- Precision Wire Processing: Engineered to strip wires without damaging the outer skin or core wire, ensuring electrical integrity. The twisting function creates tight and secure wire ends with a low failure rate.

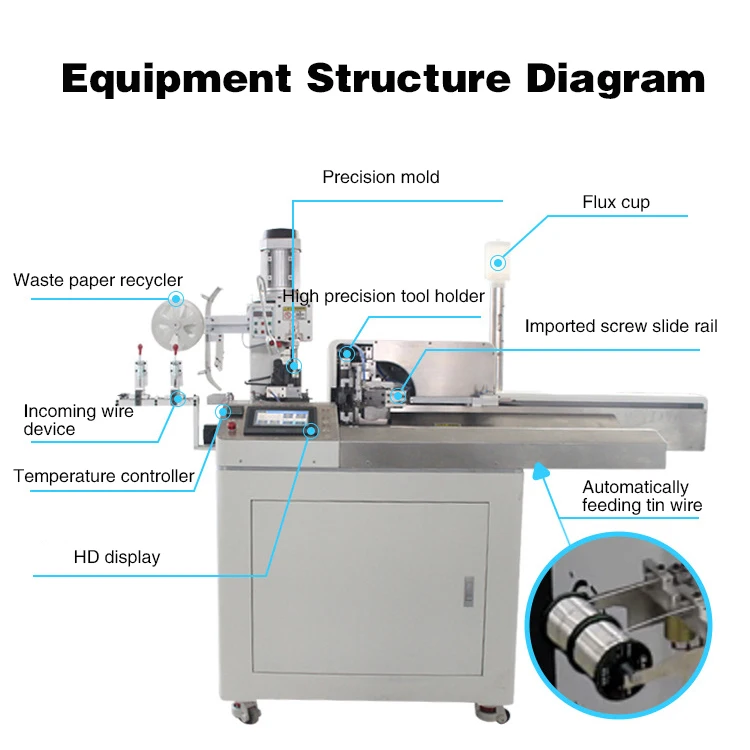

- User-Friendly Operation with Parameter Memory: Features an intuitive Chinese and English interface for easy operation. Crucially, machine parameters can be stored and recalled instantly. This eliminates the need for on-site debugging, even after shipping across long distances, ensuring plug-and-play functionality upon setup.

- Intelligent Error Compensation: Equipped with a smart system that automatically compensates and corrects discrepancies between the set peeling length and the actual stripped length, guaranteeing accuracy and reducing waste.

- Adjustable and Accurate Crimping: The crimping station is designed for precision, with adjustable terminal crimping width, height, and pressure. This ensures secure and consistent terminal crimps across various applications.

- High-Efficiency Performance: Capable of processing 18AWG-32AWG wires at an impressive rate of 8800 pieces per hour (for 8-wire processing), significantly boosting production output.

- Customizable and Versatile: Offers customizable wire range, cutting length, stripping length, twisting length, and dip tin length to accommodate a wide spectrum of wire processing requirements beyond the standard specifications.

Machine Parameters:

| Parameter | Specification | Notes |

|---|---|---|

| Machine Name | Single Head Wire Cutting, Stripping, Crimping, and Soldering/Tinning Machine | |

| Wire Range | 18AWG – 32AWG | Customizable beyond this range |

| Cutting Length | 40-1000mm | Customizable beyond this range |

| Stripping Length | 0-12mm | Customizable beyond this range |

| Twisting Length | 3-12mm | Customizable beyond this range |

| Dip Tin Length | 0-12mm | Customizable beyond this range |

| Crimping Force | 2T | |

| Working Efficiency | 8800 pcs/hour (8 wires, 18AWG-32AWG) | |

| Motor & Drive | 5 sets of Servo Motors & Drivers | Brands are selectable |

| Cylinder | Taiwan Airtac | High-quality pneumatic components |

| Slide Rail & Screw Rod | Taiwan HIWIN | Precision motion components |

Reviews

There are no reviews yet.