Achieve Precise and Reliable Flat Tape Wrapping with Our Advanced Flat Tape Wrapping Machine

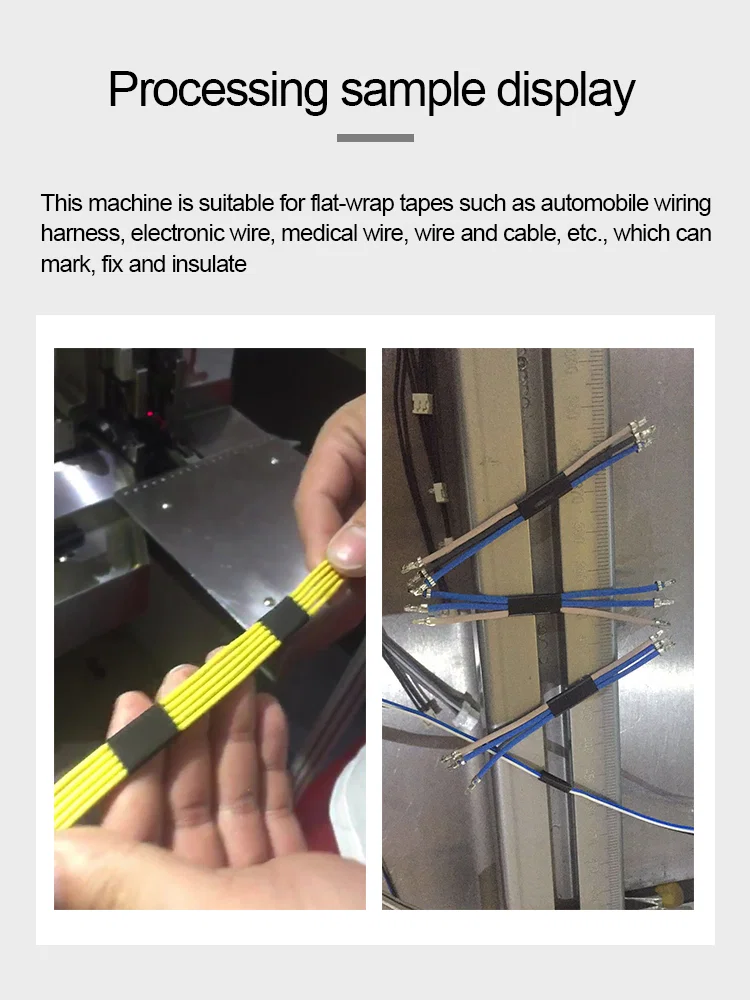

Introducing the Flat Tape Wrapping Machine, a cutting-edge solution designed for precise and efficient application of flat wrap tapes. This versatile machine is exceptionally well-suited for a wide range of applications, including automotive wiring harnesses, electronic wires, medical wires, cables, and more. It excels at performing critical functions such as marking, fixing, and insulating wires and cables using acetate adhesive tape with widths from 6 to 12 mm and a minimum thickness of 0.15 mm.

Precision and Consistency in Every Wrap

The Flat Tape Wrapping Machine is engineered to deliver superior performance, automatically wrapping up to five points with exceptional accuracy. It maintains the tape perfectly flat and wrinkle-free, ensuring a professional finish and reliable functionality. Each loop is meticulously wrapped with a consistent 1/2 overlap, guaranteeing secure and durable tape application for optimal performance and longevity.

Versatile Winding Modes and User-Friendly Controls

This machine offers remarkable flexibility with its ability to smoothly switch between different winding modes. Choose point winding at the same position for concentrated wrapping or direct spiral winding at different positions for broader coverage. Setting laps and speed is incredibly easy, allowing for fine-tuned adjustments to meet specific application requirements. The integrated output display function provides real-time production data for efficient monitoring and management.

Ideal for Post-Crimping and CNC Precision

The Flat Tape Wrapping Machine is perfectly suited for tape wrapping subsequent to crimping at the intermediate point, making it an ideal addition to automated wire processing lines. The tape length can be adjusted numerically, offering unparalleled convenience, speed, and accuracy. Utilizing automatic CNC technology, this machine ensures consistent and high-quality results with tape widths ranging from 6 to 12 mm. The efficient dressing process not only yields stable quality outcomes but also significantly reduces operational intensity for operators.

Key Features and Benefits of the Flat Tape Wrapping Machine:

- Specifically for Flat Wrap Tapes: Designed for acetate adhesive tapes used in wiring harnesses, electronic and medical wires, and cables.

- Multi-Functional: Performs marking, fixing, and insulating functions with precision.

- Wide Tape Compatibility: Handles acetate adhesive tape widths from 6 to 12 mm (minimum 0.15 mm thickness).

- Multi-Point Wrapping: Automatically wraps up to five points with consistent quality.

- Flat & Wrinkle-Free Wrapping: Ensures a professional and reliable tape application.

- Consistent 1/2 Overlap: Guarantees secure and durable wrapping.

- Versatile Winding Modes: Supports point winding and spiral winding modes.

- Adjustable Laps & Speed: Easily set and adjust wrapping parameters for diverse needs.

- Output Display: Provides real-time production data for efficient monitoring.

- Ideal for Post-Crimping: Perfect for integration into automated wire processing lines.

- Numerical Tape Length Adjustment: Offers convenience, speed, and accuracy in tape application.

- Automatic CNC Technology: Ensures stable quality and reduces operational intensity.

Optimize Your Wire Harness and Cable Wrapping Process Today!

The Flat Tape Wrapping Machine is the ultimate solution for manufacturers seeking to achieve precise, reliable, and efficient flat tape wrapping for wire harnesses, electronic wires, medical wires, and cables. Its advanced features and user-friendly design make it a valuable asset for any production environment. Contact us today to learn more about how the Flat Tape Wrapping Machine can transform your wire processing operations!

Reviews

There are no reviews yet.