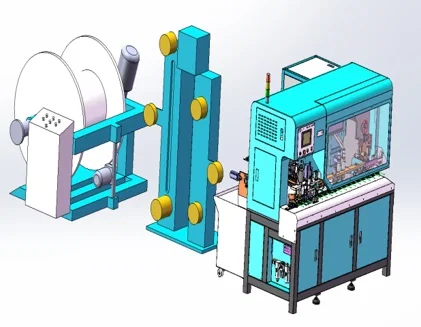

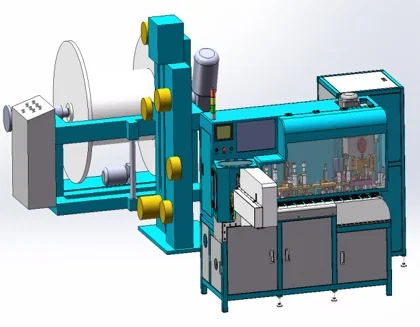

Full Automatic Us Power Cord Making Machine, Eu Plug Power Cord Cable Making Machine, Power Cable Cutting Stripping Crimping Machine

This is a highly advanced fully automatic power cord crimping machine that is designed to perform a series of crucial processes with remarkable precision and efficiency. It can effortlessly and automatically complete the tasks of wire feeding, wire cutting, stripping, polarity recognition, terminal crimping, and even defect detection. This ensures that the power cords produced are of the highest quality and meet the strictest standards.

Product details

The applicable plug inserts for this machine are extensive and can be customized to include EU, UK, US, French, Indian plug, and many others. This makes it a highly versatile option for a wide range of applications.

The efficiency of this machine is impressive, with the ability to produce 900 to 1500 pieces per hour. This high production rate can significantly boost productivity and help meet tight deadlines.

It operates with a power consumption of 6.5KW, ensuring that it has the necessary energy to perform its functions effectively.

The voltage requirement is AC220V, making it compatible with many electrical systems.

The machine requires an air pressure of 0.5 to 0.7Mpa for optimal performance.

The overall size of the machine is approximately 2 meters in length, 0.9 meters in width, and 1.8 meters in height. This size makes it suitable for a variety of workspaces.

The package includes a cable feeder, plug terminal feeder, and the main machine, providing a comprehensive solution for power cord production.

The stripping length is customizable, with the head ranging from 20 to 50mm and the tail ranging from 30 to 400mm.

The standard cutting length is 600 to 1500mm, but it can also be customized to meet specific requirements.

Features:

1. High efficiency: This machine is a game-changer when it comes to productivity. It can save four to six workers, freeing up valuable resources and significantly improving production efficiency. This allows businesses to increase output without having to hire additional staff.

2. Accuracy: The use of a servo system to control the processes of stripping the outer skin, stripping the core wire, polarity identification, and drag chain drive ensures that the equipment has extremely high precision. This results in consistent and reliable power cords.

3. Simple: Fully automated production means that this machine is not only fast but also incredibly simple to operate. Maintenance is also convenient, reducing downtime and ensuring smooth operation.

4. Security: The machine is equipped with intelligent security protection features, ensuring the safety of operators and preventing accidents.

5. Process flow: The process flow of this machine is highly streamlined and efficient. It starts with automatic wire feeding, followed by end stripping, front outer skin-stripping, brush powder removal, wire separation, shaping, stripping of inner wires, crimping of the terminal, and finally taking out the product.

Our crimping machines:

(1) Semi-auto super mute crimping machine: Available in various capacities such as 1.5T, 2T, 3T, 4T, 6T, and 8T. These machines offer a balance between performance and noise reduction.

(2) Servo motor drive crimping machine: Suitable for enameled wire splicing. This machine provides precise control and is ideal for applications that require high-quality splicing.

(3) Servo motor drive hexagon terminal crimping machine 15T. This powerful machine is designed for crimping hexagon terminals with precision and efficiency.

(4) Hydraulic hexagon/B-shape/point press terminal crimping machine 20T. With its hydraulic power, this machine can handle heavy-duty crimping tasks with ease.

(5) Auto-feeding loose terminal crimping machine, with a vibrator. This machine automates the feeding of loose terminals and ensures consistent crimping.

(6) Full auto single/double end wire cutting stripping crimping machine. This machine offers complete automation for wire cutting, stripping, and crimping at both ends.

(7) Full auto one-side crimping, one-side twisting tinning machine. This unique machine combines crimping and twisting tinning functions for added versatility.

(8) Full auto-cutting stripping crimping housing insertion machine. This comprehensive machine performs cutting, stripping, crimping, and housing insertion in one automated process.

(9) For further information, please contact us. We are always ready to answer your questions and provide detailed product information and technical support.

Reviews

There are no reviews yet.