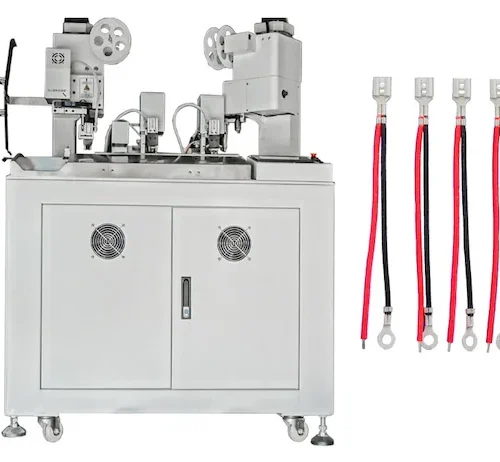

Fully Automatic Single-End 5-Wire Cutting, Stripping, Crimping, and Tinning Machine

This machine is specifically designed for the automated operations of wire cutting, stripping, single-end terminal crimping, and dip tinning at the other end. It is characterized by high efficiency and precision.

Features

– Machine Dimensions (L×W×H): 1210×770×1370 mm

– Machine Weight: 450 KG

Key Components:

1. Control System: Delta PLC

2. Cylinder: Germany Mayer

3. Solenoid Valve: Festo, Germany

4. Screw Guide: Taiwan Silver

5. Servo Motor Drive: Hechuan (Mitsubishi available as an option)

6. Pneumatic Components: SMC

7. Temperature Control Table: Omron

Advantages:

1. Factory-direct sales ensure excellent quality. The computer touch screen features a Chinese/English operation menu, which is easy to learn and operate.

2. Incorporating imported high-precision parts, the machine demonstrates stable performance.

3. The operation is straightforward. The wire length, cutting speed, tin-dipping time, and number of tin-dipping cycles can all be set via the touch screen. This enables effective tin-dipping for some wires that are challenging to process.

4. The lead-free tin furnace meets high environmental protection standards. It is equipped with an automatic tin-scraping device, ensuring that the cut wires are bright without tin residue. The tin-scraping time can be adjusted to minimize tin loss. The 90-degree tin-dipping angle results in an even tinning surface.

Place of Origin China

Usage Both ends cut, strip, one end twist dip tin, one end crimp

Warranty 1 Year

Efficiency 6000 – 8000/H (dependent on the product)

Applicable Wire AWG18 – 24 / AWG24 – 32

Cutting Length 15 – 1000 mm

Cutting Tolerance 0.2 ± 0.02× Length

Stripping Length 0 – 9 mm

Twist Length 3 – 9 mm

Tinning Length 0.5 – 9 mm

Crimping Force 2T (customizable)

Air Supply 0.5 – 0.7 MPA

Reviews

There are no reviews yet.