Automatic multiple wires can penetrate the plastic plugs shell with the help of a wire stripping position terminal crimping tinning machine. You can view the plastic shell inserting machine as well.

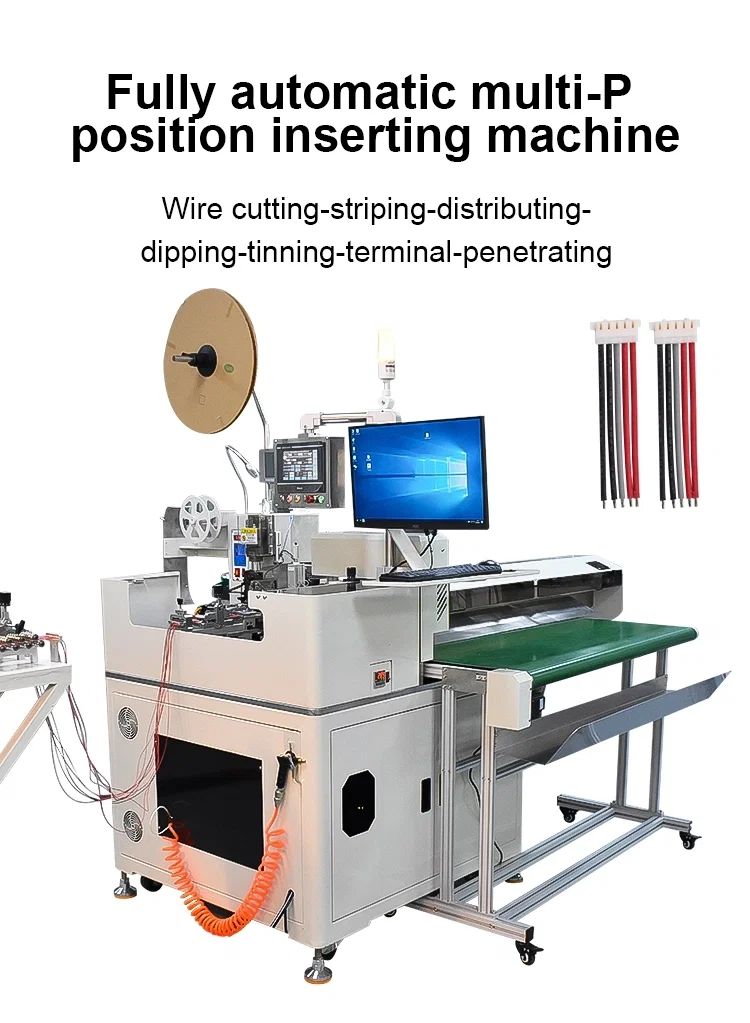

This fully automatic multi-position inserting machine offers a wide range of functions all in one. It can perform wire cutting, stripping, distributing, splitting, automatic end-making, dipping, tinning, twisting, terminal connection, and penetration, among others.

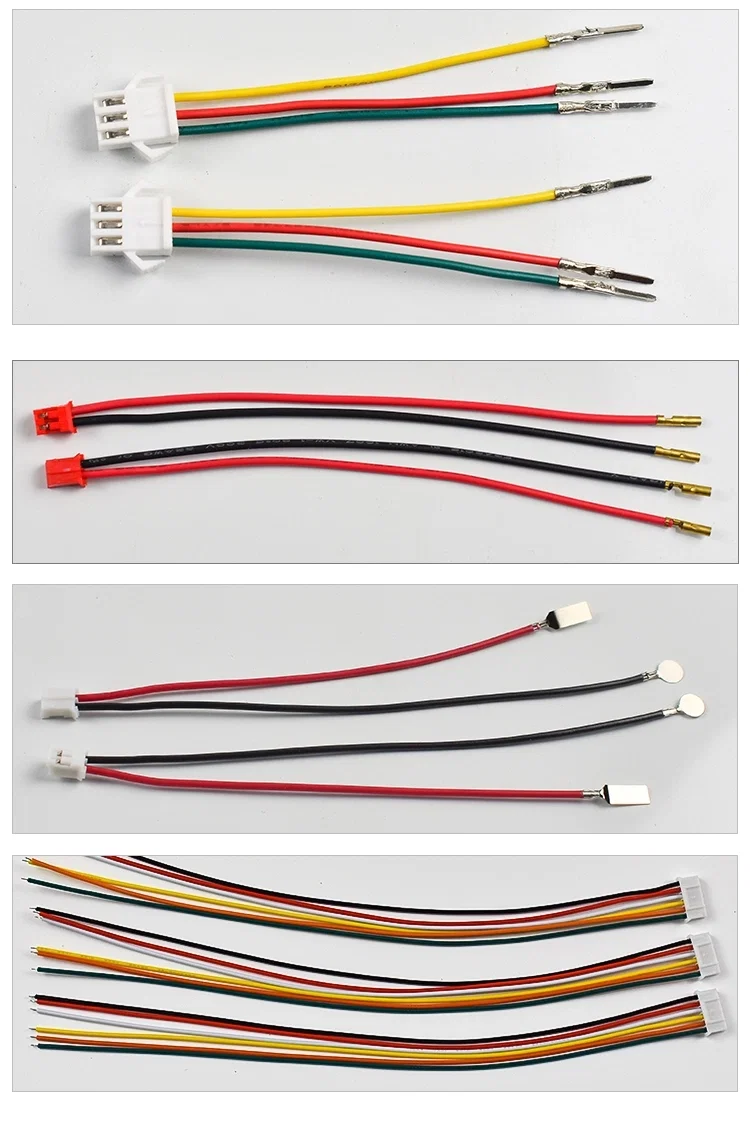

It is applicable to 12 colors of single-election wire with a single end that is tinned and shelled. There is no need to change the vibration plate for the same type of rubber shell ranging from 2P to 12P.

The operation of this machine is through a microcomputer touch screen, which is simple and convenient for debugging. It adopts a high-precision wire feeding device, ensuring smooth wire transmission without knots. The discharge is neat, there is no material jam, and it saves labor.

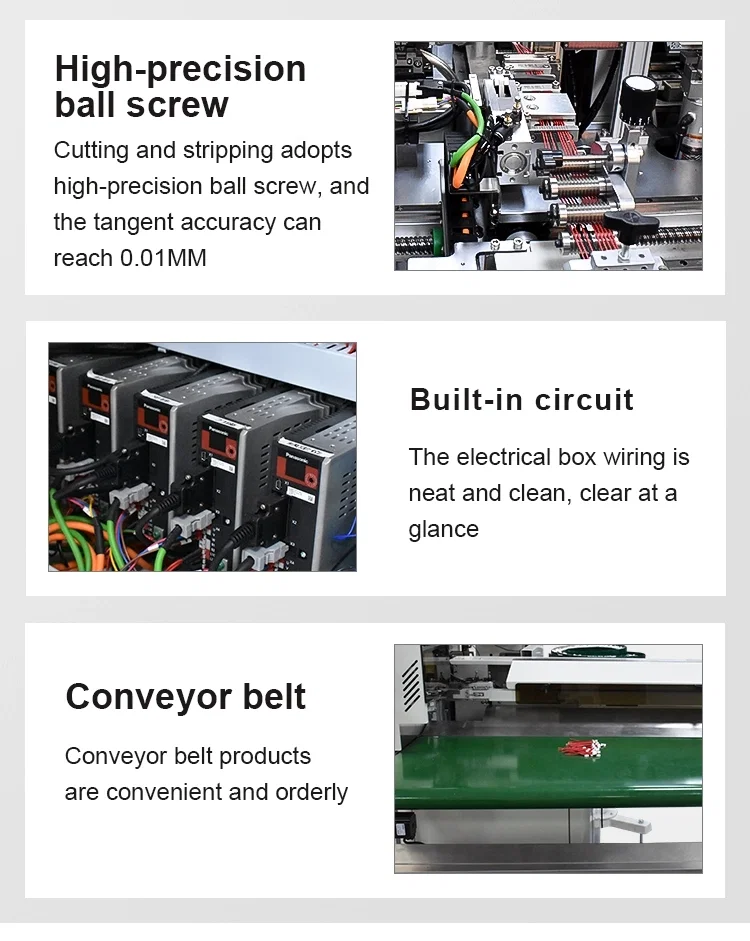

The high-precision ball screw has a tangent accuracy that can reach up to 0.01mm. The electrical box wiring is neat and clean, providing a clear view at a glance. The conveyor belt for products is convenient and ensures an orderly process.

Product Number: WPM – DPW12

Product Name: Fully automatic multi – P position inserting machine

Power Supply: AC220V 50/60HZ single phase

Cutting Length: 45mm – 1.2m

Stripping Length: 8mm before stripping (12mm can be customized), 12mm after stripping

Processing Wire: φ0.9 – 2.0 outer diameter, AWG18 – AWG28

Applicable Terminal: PH, VH, XH, SM, 1.5, PHD, 2510, etc.

Capacity: 750 – 800 times/back and forth

Crimping Ability: 1.5T

Cutting Accuracy: 0.1mm±0.01

Compressed Air: Above 5KG

Detection Device: Lack of wire alarm, lack of terminal alarm, lack of tin wire alarm (optional), pressure detection, CCD detection

Dimensions: 4.5 meters long (including pay – off stand), 2 meters wide

Machine Weight: Around 400KG

Reviews

There are no reviews yet.