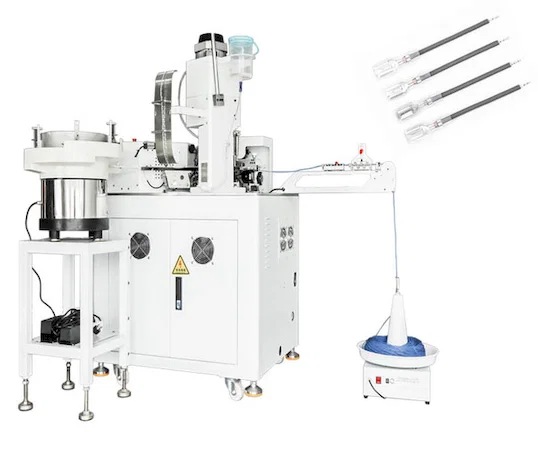

Automatic cable crimping sleeves insertion and twisting tinning machine:

This is an advanced automated, fully automatic wire processing machine that offers a wide range of functions. It is capable of performing wire cutting, stripping, crimping, sleeve insertion, and twisting tinning all in one seamless operation.

The machine is equipped with high-quality servo motors and V stripping blades, ensuring precise processing. It can handle a processing wire range from AWG24# to AWG14#, providing flexibility for various applications.

The length of wire cutting and stripping as well as the depth of wire cutting and stripping can be easily adjusted on the touch screen. This offers a convenient and simple operation experience, allowing users to customize the processing according to their specific requirements.

All the necessary parameters such as wire feeding speed, cutting length, stripping length, and crimping depth can be set and saved in the LCD touchscreen. This makes the operation extremely easy and user-friendly.

The machine features an integrated detecting function. It can detect whether the wire has exited properly, whether the terminal is present, detect wire knots, crimping quality, and air pressure levels. This helps ensure the quality and reliability of the processed wires.

By reducing set-up time and increasing effective performance, the overall productivity of the machine is significantly enhanced. Processing can be completed in less time, leading to increased efficiency and output.

It can be optionally equipped with a CFM (crimping force monitor) to closely control the crimping force during the processing. This helps maintain the high quality of the finished products and ensures consistent results.

Power Source: AC220v/50/60hz.

Capacity: Ranges from 2000pcs to 3000pcs per hour when the wire length is 300MM.

Function: Capable of wire cutting, stripping, one-side crimping with sleeve insertion and on the other side, twisting tinning.

Wire Range: AWG14# to AWG24# (can be customized according to specific needs).

Cutting Length: Can be adjusted from 80mm to 3000mm (customizable to meet different project requirements).

Cutting Accuracy: Achieves a precision of 0.5mm plus cutting length multiplied by 0.2%.

Stripping Length: Ranges from 0.5mm to 8mm (can be customized for specific applications).

Pressure: 2.0T.

Stroke: 30mm (40mm can be customized for enhanced functionality).

Air Pressure: Operates within a range of 0.5mpa to 0.6mpa.

Processing Result Display: Allows users to easily monitor and assess the quality of the processed wires.

Reviews

There are no reviews yet.