Boost Productivity with the Automatic Rotary Dispensing Robot: The High-Efficiency Automatic Rotary Dispensing Robot

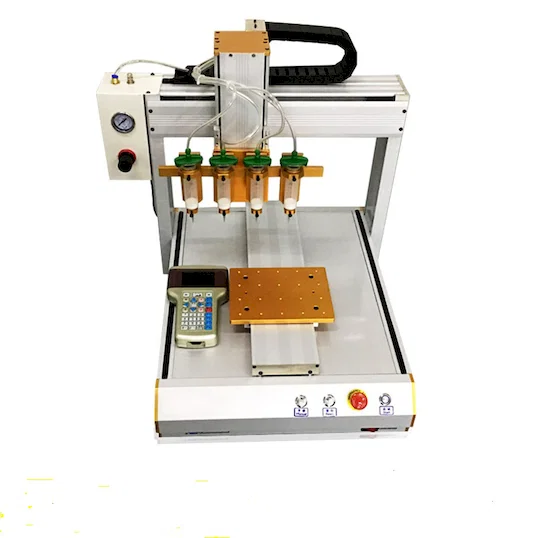

Maximize your dispensing efficiency and achieve unparalleled precision with the Automatic Rotary Dispensing Robot, a cutting-edge 4 axis dispenser robot glue system designed to transform your adhesive application processes. This high efficient glue spreader machine, also known as the Automatic Rotating Dispensing Robot, delivers automation, versatility, and unmatched accuracy for a wide spectrum of industrial applications.

This advanced Rotary Dispensing Robot is engineered to dramatically improve production output by replacing manual operation with high-precision programming. It flawlessly executes intricate dispensing patterns, applying dots, stripes, arcs, and patterns on different planes or curved surfaces with consistent accuracy and repeatability. Eliminate human error and boost throughput with this automated dispensing solution.

The Automatic Rotating Dispensing Robot is suitable for positioning different jobs, accommodating a diverse range of workpiece sizes, shapes, and materials. Its adaptable design ensures seamless integration into various production lines and workflows, maximizing its versatility across different industries and manufacturing environments.

Programming and pattern creation are streamlined with its ability to import design files. It supports graphics imported from computers, PLT files, TCF files, and G code files, allowing for direct translation of CAD designs and complex geometries into precise dispensing paths. This feature simplifies programming and enables the creation of highly customized and intricate dispensing patterns with ease.

Material versatility is a hallmark of this system. The 4 Axis Dispenser Robot Glue is suitable for glue application using an extensive range of adhesives, catering to diverse bonding and sealing requirements. It is compatible with Anaerobic, Coatings, Cyanoacrylates, White Glues, Epoxy Resin, Greases, Sealants, Silicones, Solder/Braze Pastes, Thermal Grease, Conductive Adhesive, Red Gum, UV Glue, AB Glue, Polyurethane Resin Adhesive, etc. This broad compatibility eliminates the need for multiple specialized machines, streamlining your operations and reducing equipment costs.

This Glue Spreader Machine is specifically engineered for applications demanding high efficiency, high running precision, and the production process of dispensing. It excels in scenarios requiring consistent, repeatable, and highly accurate adhesive application, making it ideal for demanding manufacturing environments. It is generally suitable for products with sensors, relays, power adapters, electronic toys, sounders, electronic components, household appliances, electric vehicle controllers, computer digital products, crafts, mobile phone boards, coil products, button products, battery boxes, speakers and much more. Specific applications include Dot glue bonding of speakers; speaker packaging and dispensing, optical semiconductor, mobile phone battery, laptop battery packaging, PCB board bonding, COB, IC, PDA, LCD sealing, IC packaging, IC bonding, chassis bonding, Optical device processing, hardware parts package coating, quantitative liquid filling, chip bonding, automotive mechanical parts coating, mechanical seals, etc. – showcasing its wide applicability across various complex and precision industries.

Invest in the Automatic Rotating Dispensing Robot and revolutionize your adhesive application processes. Experience enhanced productivity, superior precision, and unmatched versatility with this high-performance Glue Spreader Machine.

| Parameter: | |||||||

| Model | WPM-221 | WPM-331 | WPM-441 | WPM-551 | WPM-4331 | WPM-5331 | |

| Number of controlled axes | Three-axis | Four-axis | |||||

| Effective travel | X axis | 200mm | 300mm | 400mm | 500mm | 400mm | 500mm |

| Y1 axis | 200mm | 300mm | 400mm | 500mm | 300mm | 300mm | |

| Y2 axis | 300mm | 300mm | |||||

| Z axis | 50mm | 100mm | 100mm | 100mm | 100mm | 100mm | |

| Transmission mode | Double-track timing belt | ||||||

| Power source | Stepper motor | ||||||

| Top speed | 500mm/sec | ||||||

| Repeat accuracy | ±0.05mm | ||||||

| Maximum load | X/Y/Z 5kg/5kg/2kg | ||||||

| Control System | Hand-held three-axis control system | ||||||

| File storage space | 400 sets of processing files, up to 9999 points in a single file. | ||||||

| Power | AC110-250V 50-60HZ 350W | ||||||

| Size | L | 475mm | 520mm | 620mm | 720mm | 620mm | 720mm |

| W | 410mm | 585mm | 685mm | 785mm | 585mm | 585mm | |

| H | 522.5mm | 596.5mm | 596.5mm | 596.5mm | 596.5mm | 596.5mm | |

| Weight | 35kg | 44kg | 59kg | 65kg | 63kg | 62kg | |

| 二、Main accessories: | |||||||

| 1 | motor | Stepper motor | |||||

| 2 | Drive | YAKO (China) | |||||

| 3 | Linear Guides | (Taiwan) X / Y axis dual rail, single rail | |||||

| 4 | Three-axis control system | (China) | |||||

| 5 | Power supply | (China) | |||||

Reviews

There are no reviews yet.