High-Precision Automatic Touch Screen Gold Wire Sealing Machine – Integrated Solution for Wire Bundling and Sealing Packaging

(Smart Touch Screen Gold Wire Sealing Machine – Efficient & Precise Wire Bundling Expert )

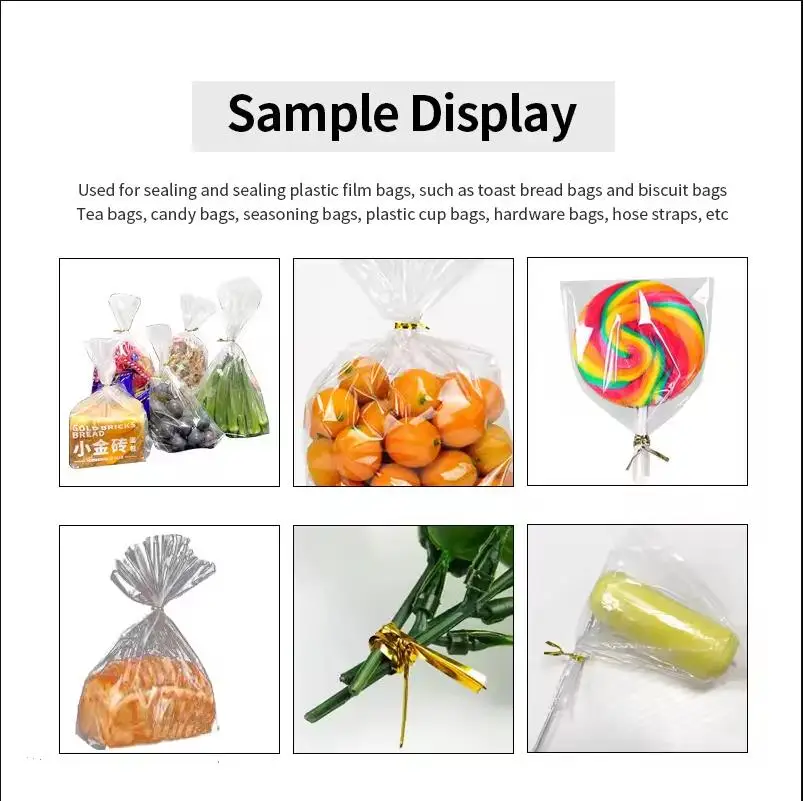

Step into Automated Efficiency, Bid Farewell to Manual Bundling! High-Precision Automatic Touch Screen Gold Wire Sealing Machine is an intelligent device meticulously designed for wire bundling and sealing packaging. Equipped with an advanced touch screen control system, it offers simple operation and reliable performance. Significantly enhance the packaging efficiency and aesthetic appeal of wire products, while effectively reducing labor costs.

Core Advantages and Features:

- Intelligent Touch Screen Operation, Simple & Convenient: Features a high-definition touch screen with a user-friendly and intuitive interface. Parameter settings and mode switching are clearly displayed at a glance. Operators, even without specialized skills, can easily get started and quickly master the operation of the equipment.

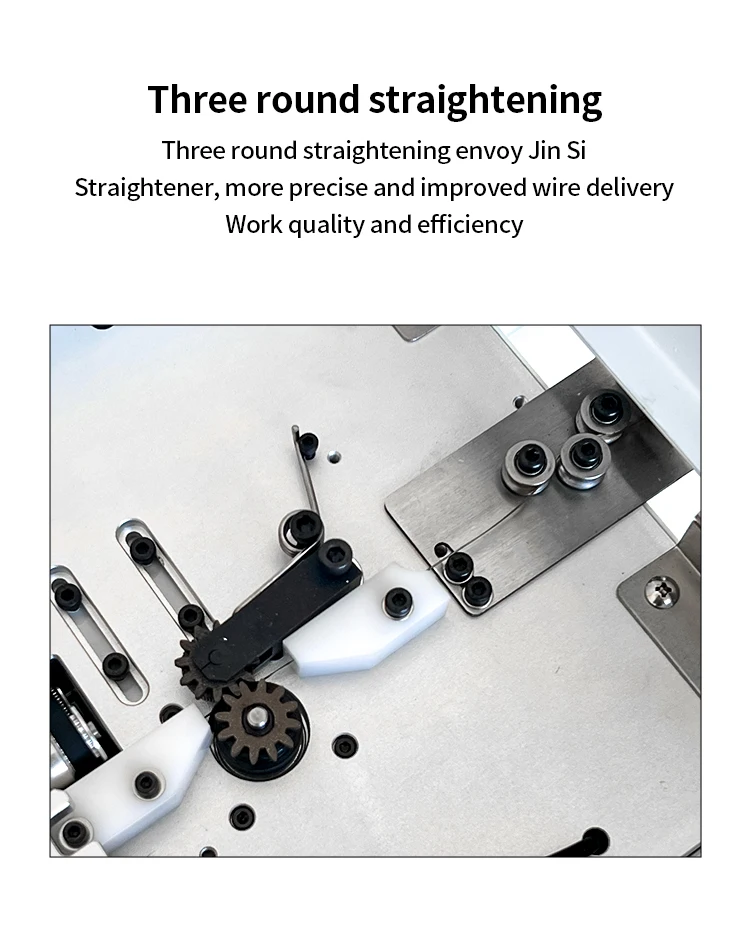

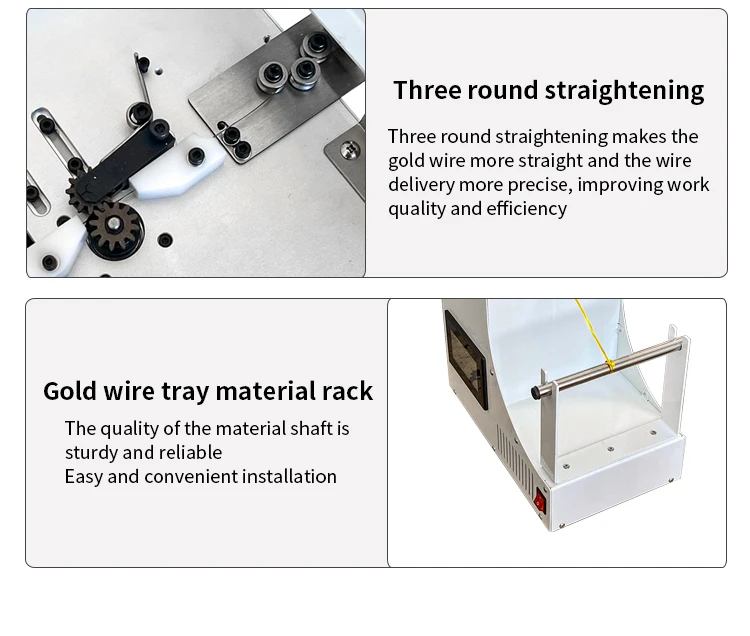

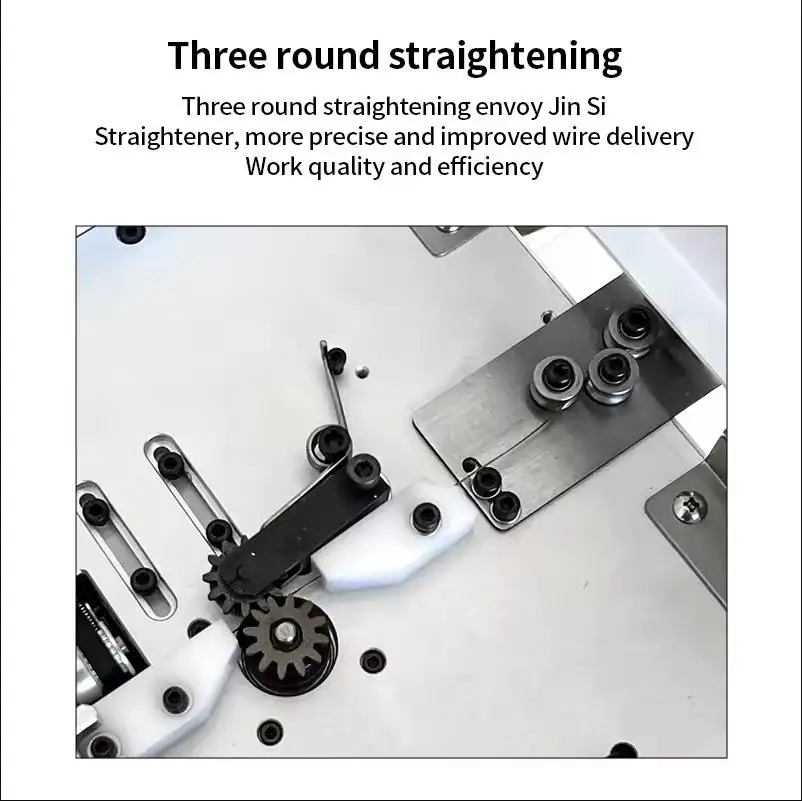

- High-Precision Automatic Sealing, Guaranteed Quality: Employs a precision wire feeding mechanism and stable sealing technology to ensure consistent sealing force and accurate positioning for every gold wire. Achieves a high yield rate, significantly improving product packaging quality and grade.

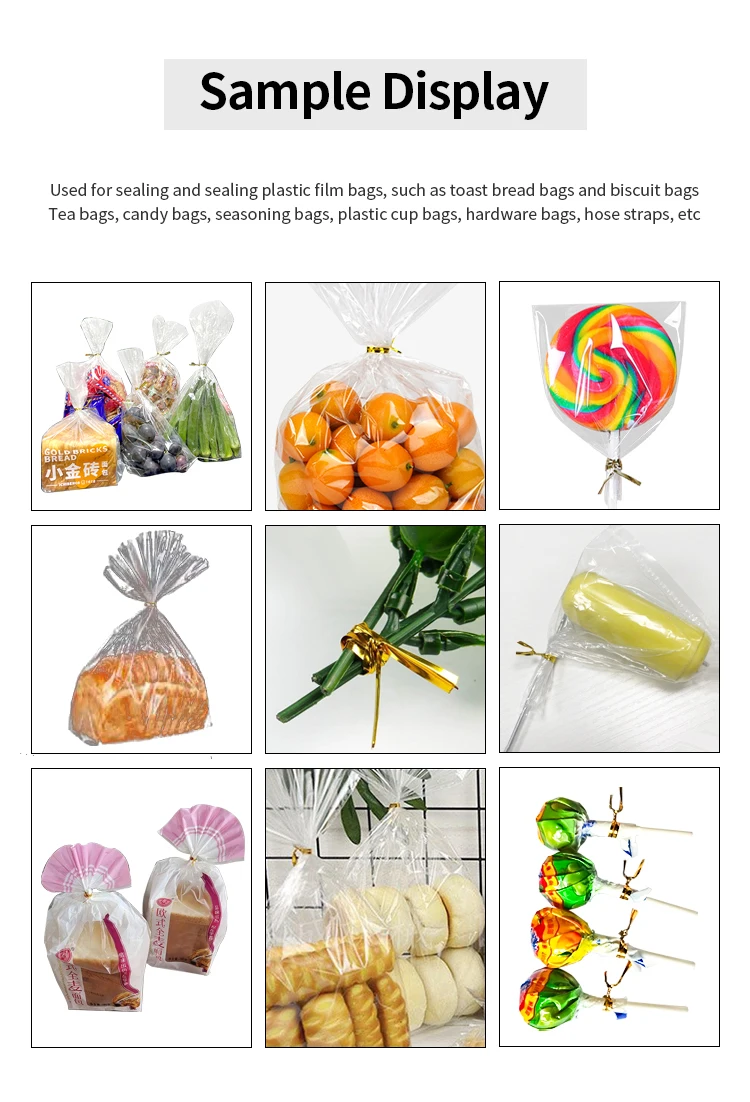

- Wide Wire Diameter Compatibility, Flexible Application: Wire diameter range of 2-15mm makes it suitable for various specifications of wires, such as electronic wires, power cords, data cables, etc. Handles both delicate and fine gold wires and thicker cables with ease, meeting diverse wire bundling and sealing needs.

- Adjustable Number of Coils, Customized Packaging: The number of coil windings can be freely set as required, enabling personalized and customized packaging effects. Whether you need tight bundling or loose packaging, precise control is achievable to meet diverse packaging requirements.

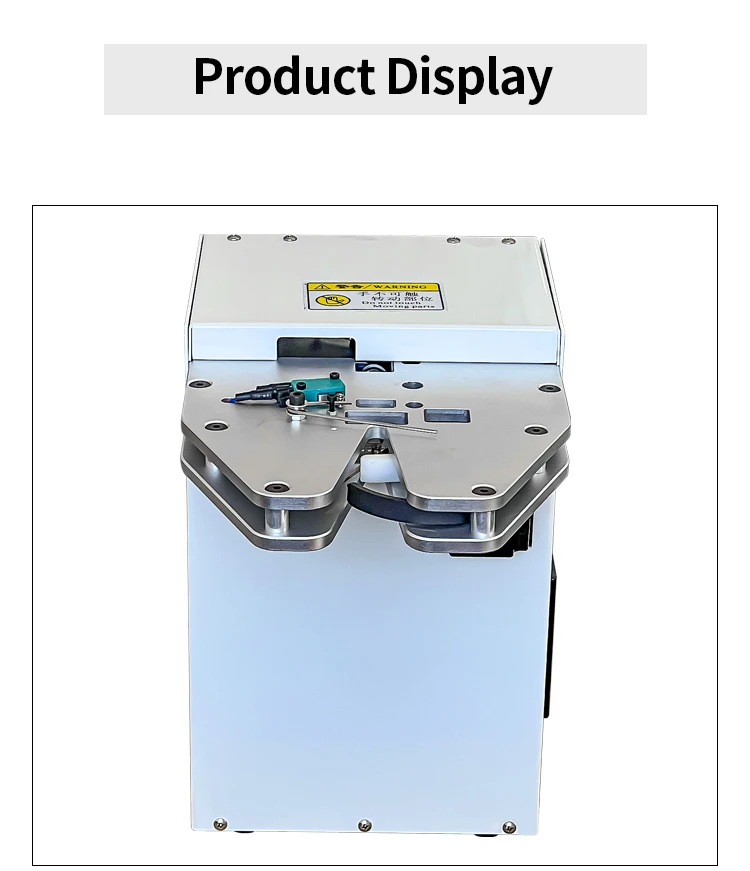

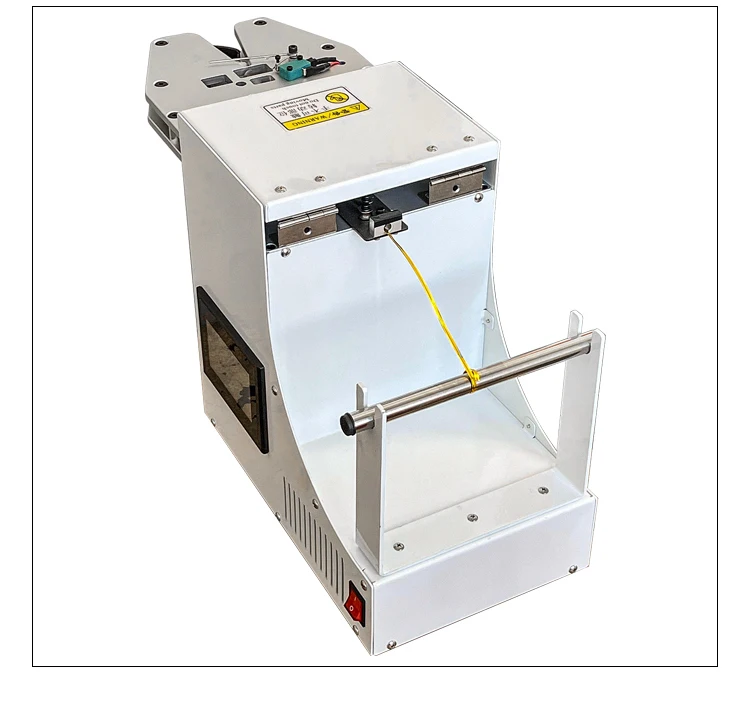

- Compact Size, Space-Saving: Dimensions of only 350220340mm with a compact machine design and small footprint. It can be flexibly deployed at various stages of the production line, effectively saving space and improving site utilization.

- Stable and Reliable, Durable Performance: Robust machine structure and carefully selected high-quality components. A machine body weight of 20 kilograms ensures smooth operation, low vibration, and guarantees long-term stable and reliable operation of the equipment, reducing maintenance costs.

- Safe and Environmentally Friendly, Worry-Free Use: Complies with environmental standards and no high-concerned chemicals are used (Hign-concerned Chemical: None). Production process is safe and reliable, safeguarding operator health and a clean production environment.

Technical Parameters:

- Product Type: Automatic Touch Screen Gold Wire Sealing Machine

- Applicable Wire Types: Electronic wires, power cords, data cables, and various other wire types

- Wire Diameter Range: 2-15mm

- Number of Coils Wound: Set as required

- Control System: Touch Screen Control

- Dimensions: 350mm (Length) x 220mm (Width) x 340mm (Height)

- Weight: 20 kilograms

- High-concerned Chemical: None

- Origin: Mainland China

Suitable Industries and Applications:

- Electronics and Electrical Industry: Bundling and sealing packaging for various electronic wire harnesses, connecting wires, data cables, and power cords.

- Toy and Gift Industry: Wire bundling and securing for toy and gift accessories.

- Other Manufacturing Industries: Production of various products requiring wire bundling and sealing packaging.

Reasons to Choose Automatic Touch Screen Gold Wire Sealing Machine:

- Increase Efficiency, Reduce Costs: Automated operation significantly improves packaging efficiency, saves labor costs, and shortens production cycles.

- Improve Quality, Enhance Competitiveness: Uniform and standardized sealing effect enhances product packaging quality and aesthetics, increasing product market competitiveness.

- Easy Operation, Simple Maintenance: Touch screen operation is simple to learn and use, maintenance is convenient, reducing operator training costs and maintenance expenses.

- Stable and Reliable, Durable Performance: High-quality materials and refined craftsmanship ensure long-term stable operation of the equipment and minimize downtime.

- Wide Application, Flexible Adaptation: Suitable for a variety of wire materials and packaging requirements, meeting application scenarios for different industries and customers.

Inquire Now for a Discounted Quote and More Details!

(Adding product images, touch screen operation interface images, images of bundling effects for different wires, application scenario images, customer case study videos, etc., can further enhance the attractiveness of the product description.)

Reviews

There are no reviews yet.