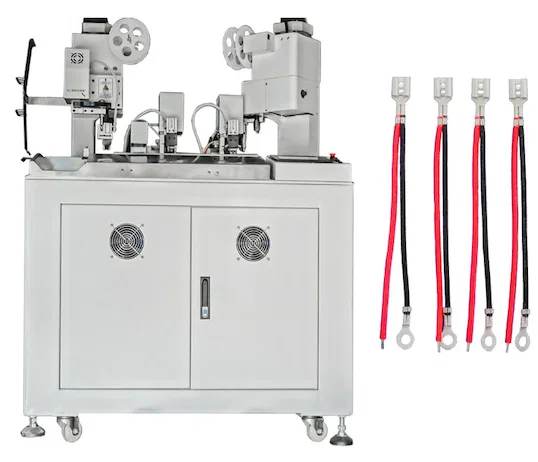

Automatic three-sided two wires crimping machine:

This is a highly advanced, fully automatic wire harness processing machine. It is designed to perform multiple functions with precision and efficiency. The machine is capable of two wires cutting, stripping, and three ends terminal crimping. This comprehensive functionality makes it an essential tool for wire harness manufacturing processes.

The technical parameters of this machine can be conveniently set on a PLC controlled touch display. The display features an English operation interface, ensuring ease of use for operators from different regions. The machine is controlled by a powerful servo motor, which plays a crucial role in ensuring the precision of various operations. This includes the cutting length, cutting tolerance, stripping, and crimping. With such precise control, the machine can produce high-quality wire harnesses with consistent results.

The machine is equipped with different feeding tubes that are specifically designed for feeding different wire sizes ranging from AWG28# to AWG16#. This flexibility allows for the processing of a wide variety of wires, meeting the diverse needs of different applications. Additionally, OTP horizontal mold and straight mold can be used in this machine. Moreover, European mold or Korean mold can also be utilized, providing further options for users.

In terms of power requirements, the machine operates on AC220v/50/60hz. It offers several important functions. Firstly, it can perform cutting and stripping of two different wires. On one side, it can crimp both wires in one terminal. On the other side, each wire can be crimped to a different terminal. This versatility makes it suitable for a wide range of wire harness configurations.

The capacity of the machine is impressive, capable of producing 4000pcs/h when the wire length is L=150MM. The wire range is from AWG28# to AWG16#, and this can be customized according to specific requirements. The cutting length can range from 65 to 9999mm and can also be customized. The cutting accuracy is maintained at a high level, with a tolerance of 0.5mm + cutting length x 0.2%. The stripping length can be set from 0.5 to 8mm and is also customizable.

The crimping force of the machine is 2.0T, ensuring a secure connection. The crimping stroke is 30mm, with 40mm being an optional choice. The applicator range includes OTP applicator, European applicator, and Korean applicator, providing flexibility in choosing the appropriate applicator for different applications.

The machine requires an air pressure of 5-6kgf for optimal operation. The size of the machine is 1090*1000*1980mm, and it weighs 390kg. This size and weight make it suitable for installation in various production environments.

processing result display

Reviews

There are no reviews yet.