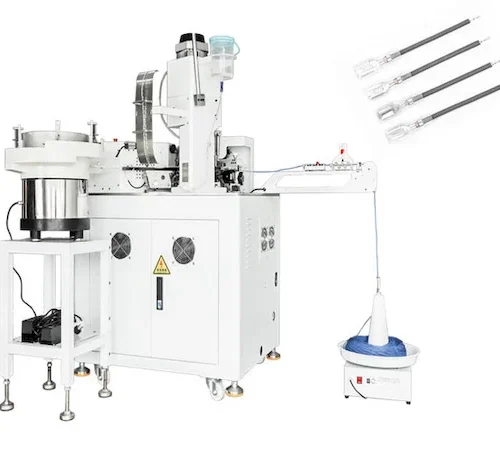

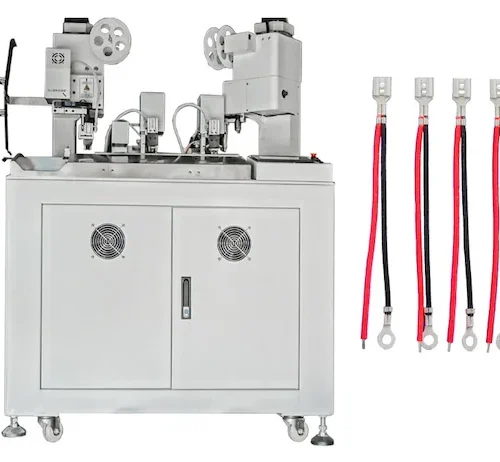

Fully Automatic Dual-End 5-Wire Cutting, Stripping, Twisting and Tinning Machine

Wire Cutting, Stripping and Tinning Machine; 5-Wire Cutting, Stripping and Tinning Machine; Automatic Dual-End Wire Tinning Machine

Specification

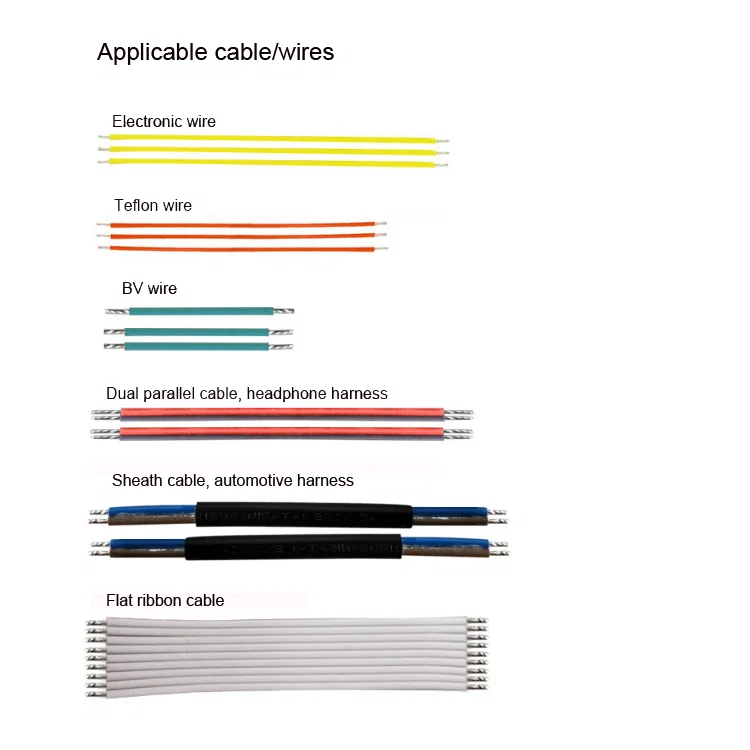

This machine is engineered to automatically cut, strip, twist and tin flat cables and single wires, boasting high efficiency and precision.

(1) For single wires, the machine can be configured to output 1, 3, 5 or 8 wires in one operation, with the quantity determined by the wire diameter.

(2) Applicable for flat cables, ribbon cables and flat sheathed cables.

Item Details

Place of Origin: China

Usage: Cutting, Stripping, Twisting, Tinning

Warranty: 1 Year

Efficiency (1 output 3): 32 – 20AWG, 2700 – 4000 pieces per hour

Efficiency (1 output 8): 20 – 16AWG, 6400 – 10000 pieces per hour

Applicable Wire: AWG18 – 24 / AWG24 – 32

Cutting Length: 30 – 550mm (minimum 8mm, customizable)

Cutting Tolerance: 0.2 ± 0.02 * Length

Stripping Length: 0 – 9mm

Twisting Length: 3 – 9mm

Tinning Length: 0.5 – 9mm

Air Supply: 0.5 – 0.7MPa

Features

Machine Dimensions (L * W * H): 1210 * 770 * 1370mm

Machine Weight: 400KG

Component Details:

Control System: Delta PLC

Cylinder: Germany Mayer

Solenoid Valve: Festo, Germany

Screw Guide: Taiwan Silver

Servo Motor Drive: Hechuan (Mitsubishi available as an option)

Pneumatic Components: SMC

Temperature Control Panel: Omron

Advantages:

– Factory-direct sales ensure excellent quality. The computer touch screen with a Chinese operation menu is easy to learn and operate.

– Utilizes imported high-precision components, ensuring stable performance.

– The operation is straightforward. Parameters such as wire length, cutting speed, tin immersion time and tin dipping times can be easily adjusted via the touch screen. This also enables effective tinning of some wires that are difficult to process.

– The lead-free tin furnace meets high environmental protection standards. It is equipped with an automatic tin scraping device, ensuring that the cut wires are bright and free of tin residues. The tin scraping time can be set to minimize tin loss. The 90-degree tin dipping angle results in an even tinning finish.

Reviews

There are no reviews yet.