Headline: Boost Productivity with the WPM-5-40: Your Premier Semi-Automatic Wire Strip Crimp Machine for Ferrule Terminals

Introduction:

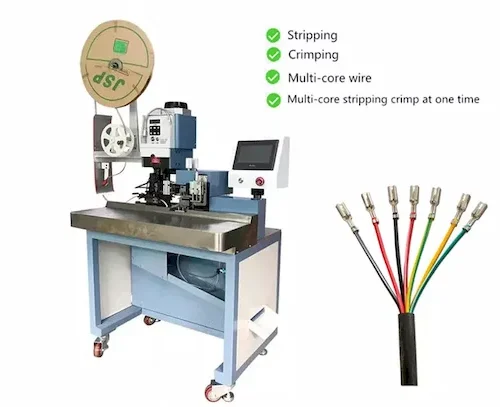

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. The WPM-5-40 Semi-automatic Ferrule Terminal Crimping Machine / Wire Strip and Crimp Machine is engineered to elevate your wire processing capabilities, offering a robust and reliable solution for Bulk Tube Pre-insulation Terminal Crimping and Tube Pre-insulation Terminal Crimping. This advanced Wire Strip Crimp Machine is designed for high-volume production, delivering exceptional performance and consistent quality for all your pipe-type terminal applications.

Key Features and Benefits:

- High-Speed Crimping for Enhanced Throughput: Achieve rapid production with a cycle time of just 2.5 seconds. The WPM-5-40 significantly boosts your output, allowing you to meet demanding production schedules with ease.

- Precise and Consistent Quadrilateral Crimp: Guarantee secure and reliable electrical connections with the machine’s quadrilateral crimp shape. This ensures optimal conductivity and long-lasting performance for your wire assemblies.

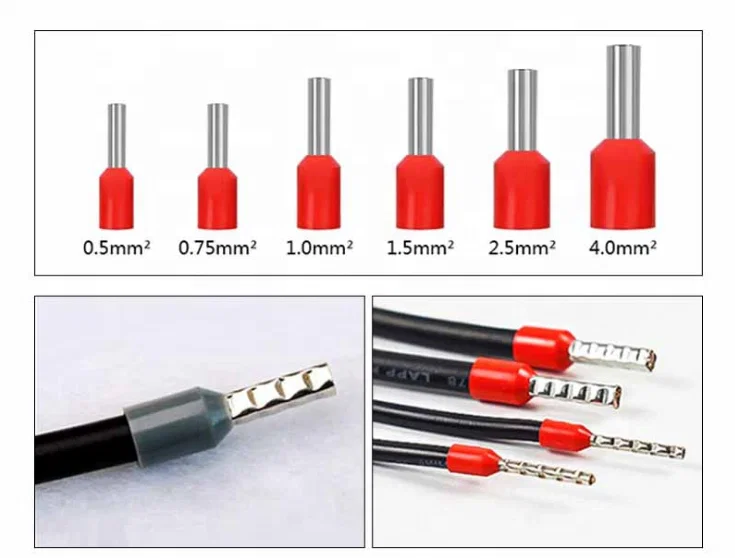

- Versatile Wire Compatibility: Process a wide range of BVR wires, including 0.5, 0.75, 1.0, 1.5, 2.5, and 4.0 square millimeters. This versatility makes the WPM-5-40 adaptable to various application needs.

- Specifically Designed for Pipe-Type Terminals: This machine excels at processing pipe-type terminals, accommodating insulator lengths up to 7.5mm and conductor lengths up to 10mm.

- Semi-Automatic Operation for Optimal Efficiency: Combining automated crimping with manual component replacement and adjustments, the WPM-5-40 offers the perfect balance of automation and flexibility.

- User-Friendly Man-Machine Interface: The intuitive interface simplifies operation and control, allowing for easy adjustments and monitoring of the crimping process.

- Dual Operation Modes: Adapt to different production needs with both automatic trigger and manual operation modes, providing flexibility and control over your workflow.

- Comprehensive Safety Features: Integrated safety mechanisms, including terminal presence/absence detection and safety door verification, ensure operator safety and minimize errors during operation.

- Compact and Robust Design: With dimensions of 350 mm × 450 mm × 400 mm and a weight of 40 kg, the WPM-5-40 is space-saving and easily integrated into your production line, while maintaining a robust build for long-term reliability.

- Pneumatic and Electronic Control: Leveraging both pneumatic and electronic control systems, the machine delivers smooth, reliable, and precise operation.

Technical Specifications:

| Feature | Specification |

|---|---|

| Model | WPM – 5 – 40 |

| Product Name | Pipe – type Terminal Automatic Peeling and Crimping Machine |

| Keyword Focus | Wire Strip Crimp Machine, Semi – automatic Ferrule Terminal Crimping Machine, Bulk Tube Pre – insulation Terminal Crimping Machine, Tube Pre – insulation Terminal Crimping Machine |

| Power Supply | AC220V, 50/60Hz |

| Gas Source | 0.6 – 0.8 MPA |

| Crimp Shape | Quadrilateral Crimp |

| Production Capacity | 2.5 seconds per cycle |

| Operating Temperature | 10°C – 25°C |

| Working Humidity | 30% – 80%RH (Relative Humidity) |

| Weight | 40 kg |

| Dimensions | 350 mm × 450 mm × 400 mm |

| Control Method | Man – Machine Interface, Electronic Control, Pneumatic Control |

| Operation Mode | Automatic Trigger / Manual Operation |

| Applicable Wires | BVR wires of 0.5, 0.75, 1.0, 1.5, 2.5, 4.0 sq mm |

| Terminal Specification | Insulator length < 7.5 mm, Conductor length < 10 mm |

| Test Items | Terminal presence/absence detection, Safety door verification |

Reviews

There are no reviews yet.