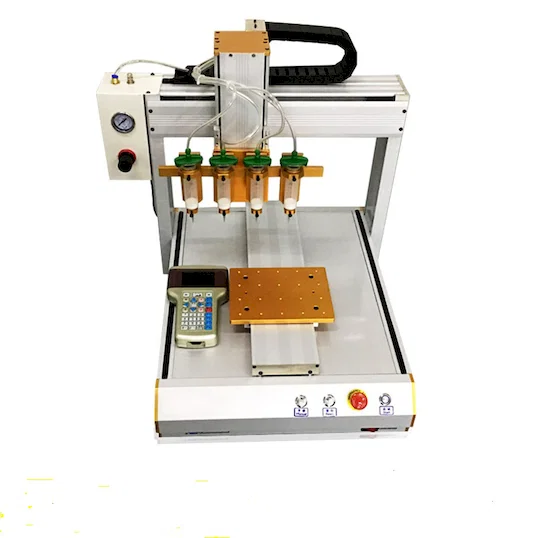

Automatic glue dispenser machine, Automatic Rotating Dispensing Robot, 4 Axis Dispenser Robot Glue, and Glue Spreader Machine offer advanced dispensing solutions.

The pressure regulating valve is responsible for adjusting the inside pressure of the syringe. The pressure adjustment range spans from 0.05 to 0.9 MPa. When performing the adjustment, the process is as follows. Firstly, pull out the knob. Turning it clockwise leads to an increase in pressure, while turning it counterclockwise results in a decrease. Once the adjustment is complete, press the knob back.

The controller switch serves the purpose of turning on or off the power supply within the control box.

The Y-axis slider plays a crucial role in driving the substrate to move back and forth smoothly.

The pressure gauge displays the pressure after regulation, providing clear and immediate feedback on the adjusted pressure level.

The manual glue button, when pressed, causes the needle to dispense glue. Releasing the button halts the glue flow.

The X-axis controls the needle’s movement from left to right with precision.

The Z-axis is responsible for controlling the needle’s up and down movement.

The reference plate is utilized for placing workpieces or fixtures. It provides a stable surface for the dispensing process.

The Y-axis also controls the movement of the reference plate back and forth, enabling accurate positioning.

The base houses the internal electrical control systems, ensuring the proper functioning of the machine.

The reset switch allows for pausing the running program and returning it to the origin. After the machine is reset, teaching can be programmed for customized dispensing operations.

For the fixture hanging plate, one can install either the syringe or the dispensing valve. The specific choice depends on the process requirements.

The emergency stop button, when pressed, immediately aborts the program and stops the device, ensuring safety in case of emergencies.

The Start/Reset/Pause button serves multiple functions. When turned on or after the emergency stop is released, it acts as the system reset switch. After reset, it becomes the device running switch. Once the device is running, it can also function as the pause switch.

| Maximum speed | 300mm/s(Can be customized up to 800mm/s) |

| Repeat accuracy | ±0.02mm-0.05mm(Can be customized within±0.02mm) |

| Control system | Cooperate with domestic listed companies to develop teaching hand-held control system |

| Drive mode | Step/servo motor(imported from Japan), synchronous belt/Screw mandrel, Linear slide-way(Taiwan brand) |

| Program storage | It can store 1,000 sets of processing data, and a single processing file can occupy up to 3M storage space(5,000 processing points) |

| File storage space | Hand-held box 256M, card remover 32M, and a single processing file can occupy up to 3M storage space(100,000 processing points) |

| Support document | CAD、CORELDRAW |

| Maximum load | Y axis/Z axis 5KG/2KG |

| Power supply | AC220V/110V, 50-60HZ, 350W |

Reviews

There are no reviews yet.