Automate Loose Terminal Crimping with Our High-Speed Machine: Boost Efficiency & Cut Costs Now!

Introduction:

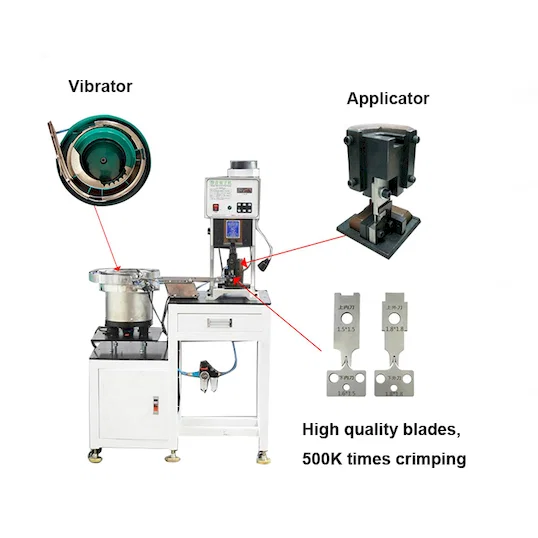

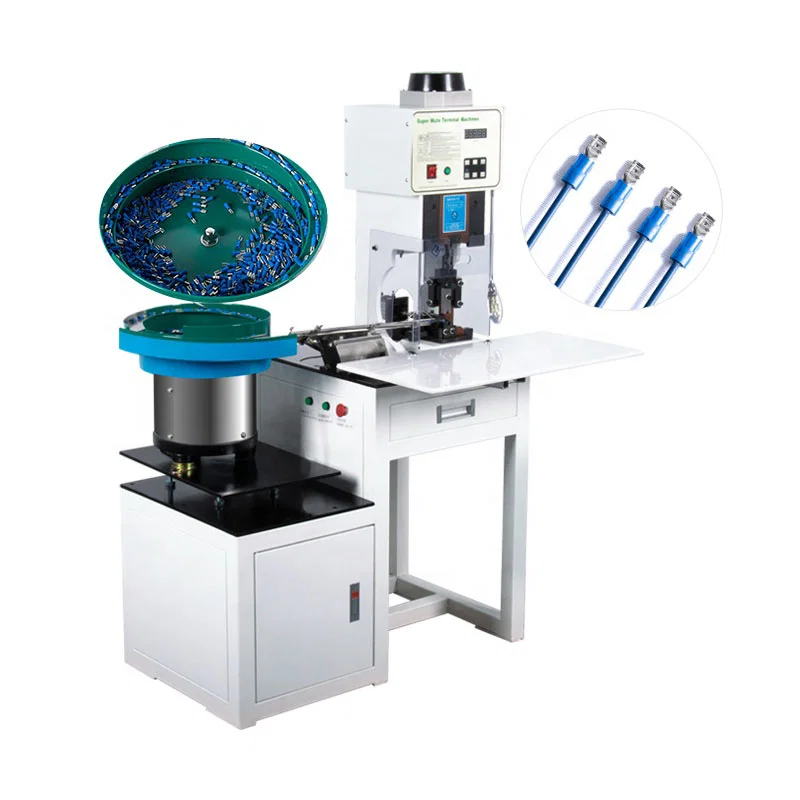

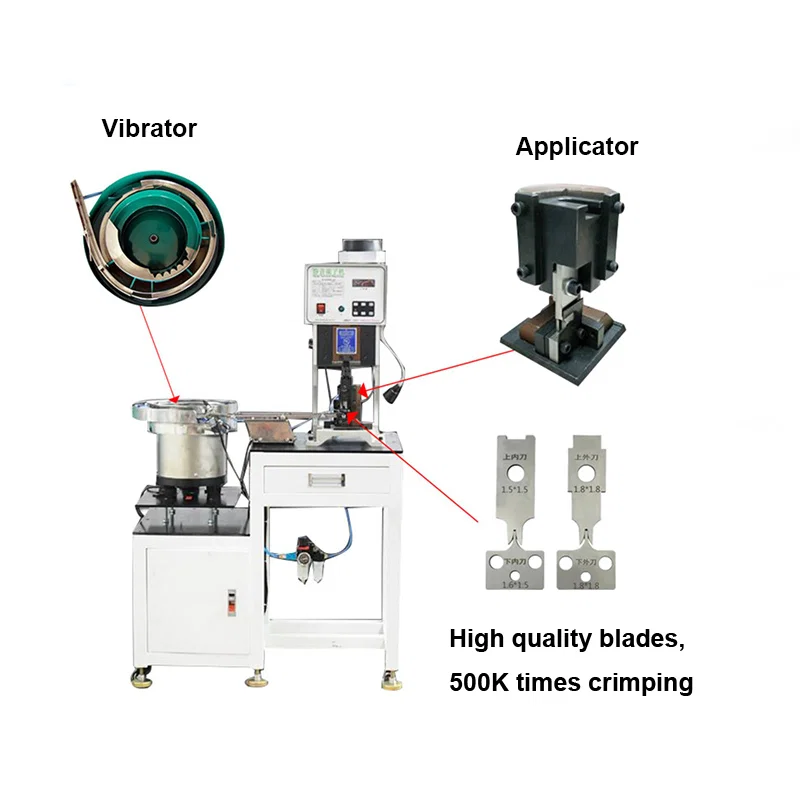

Introducing the revolutionary Loose Terminals Crimping Machine With Vibration Plate Feeding, a semi-automatic powerhouse designed to transform your cable connector crimping processes. This cutting-edge machine is specifically engineered for efficient and high-speed crimping of loose terminals, utilizing an innovative vibration plate feeding system for seamless operation. Offering operating speeds comparable to chain terminal machines, this Loose Terminals Crimping Machine delivers significant labor and cost savings, providing a remarkably cost-effective advantage for your production line. Streamline your workflow, maximize your output, and reduce your operational expenses with this essential automation solution for loose piece terminal crimping.

Key Features and Benefits:

- Semi-Automatic Operation for Optimized Efficiency and Reduced Labor: This Loose Terminals Crimping Machine offers semi-automatic operation, balancing manual tasks with automated processes to significantly reduce labor requirements while maintaining high throughput and efficiency in loose terminal crimping.

- Vibration Plate Feeding System for Automated Terminal Supply: Featuring a vibration plate feeding system, this machine automatically arranges and feeds loose piece terminals, ensuring a consistent and reliable terminal supply directly to the crimping die. Eliminate manual terminal placement and streamline your process.

- High-Speed Operation Comparable to Chain Terminal Machines: Experience operating speeds comparable to more expensive chain terminal crimping machines. This Loose Terminals Crimping Machine delivers a high crimping rate of 60-70 terminals per minute (regular terminals), achieving a remarkable output of 3000-4000 pieces per hour, significantly boosting your production volume. (Note: speed may vary for special terminals).

- Cost-Effective Solution with Labor and Cost Savings: This Loose Terminals Crimping Machine provides a highly cost-effective solution compared to chain terminal machines and manual crimping methods. Save on both labor costs through automation and reduce material waste with efficient terminal feeding.

- Manual Operation Part for User Control and Flexibility: Includes manual operation steps for user control and flexibility. Operators manually load terminals into the vibration plate and manually position the wire into the terminal before crimping, allowing for operator oversight and adjustments.

- Automated Machine Running Part for Consistent and Rapid Crimping Cycles: The machine running part automates key processes including terminal arrangement, feeding, and crimping. Once ready, a simple start of the crimp switch initiates an automated crimping cycle, ensuring consistent and rapid crimping completion.

- High Crimping Speed (Up to 120 PCS/MIN) for Maximized Throughput: Achieve a high crimping rate of up to 120 pieces per minute, further maximizing your throughput and minimizing cycle times with this rapid Loose Terminals Crimping Machine.

- Precise and Consistent Crimping with 2.0T Crimping Capacity and Adjustable Closing Height: Benefit from a 2.0T crimping capacity and adjustable closing height, ensuring precise and consistent crimping results across various terminal and wire combinations. Maintain high-quality crimps and reduce defects.

Technical Specifications:

| Feature | Specification |

|---|---|

| Product Type | Loose Terminals Crimping Machine |

| Keyword Focus | Loose Terminals Crimping Machine |

| Operation Type | Semi-Automatic with Vibration Plate Feeding |

| Terminal Feeding | Vibration Plate Feeding |

| Applicable Terminals | Loose Piece Terminals |

| Crimping Capacity | 2.0T |

| Crimping Speed (Regular Terminals) | 60-70 PCS/MIN (3000-4000 PCS/Hour) |

| Maximum Crimping Speed | 120 PCS/MIN |

| Stroke of Slide Block | 30MM |

| Closing Height | 126MM |

| Closing Height Adjustment | 10MM |

| Voltage | AC220V/50HZ |

| Consumed Power | Motor: 250W, Working Lamp: 60W, Vibrating Plate: 120W |

| Dimension (MM) | 4508001200(MM) |

| Weight | 160KG |

| Key Benefits | High Speed, Labor Saving, Cost-Effective, Vibration Plate Feeding, Semi-Automatic Operation |

Reviews

There are no reviews yet.