Premium Terminal Machine Blades – Unrivaled Durability and Precision for Wire Crimping (OTP Blades & More)

Introduction:

Tired of Terminal machine blades that crack and fail, forcing daily replacements and disrupting your production? The terminal cutting die is a critical component in electronic wiring harness processing, and compromised blades lead to significant downtime and increased costs. Many companies, in an effort to save upfront, opt for inferior domestic steel, resulting in Wire Strip And Crimp Machine Dies that lack the necessary hardness and longevity. Our Assembly Knife For Crimp Machine and Crimping Knife solutions are different. We utilize premium Japan high-quality steel, meticulously processed with vacuum heat treatment ten times to achieve unparalleled punching power and durability. Say goodbye to daily blade changes and hello to lasting performance with our superior terminal machine blades.

Key Features for Superior Performance and Longevity:

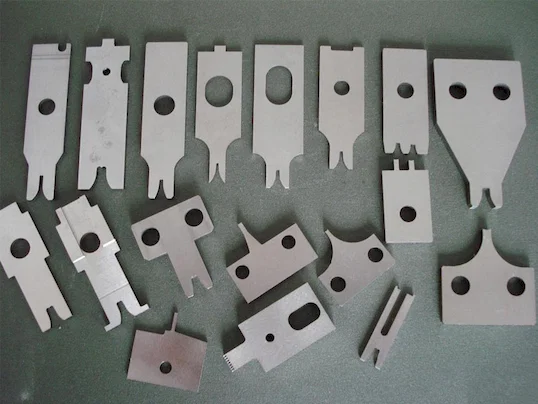

Our Terminal machine blades, including OTP blades, are engineered for exceptional durability and precision:

- Premium Japanese DC53 Steel: Crafted from imported Japanese DC53 steel, renowned for its exceptional strength and wear resistance, guaranteeing superior performance and longevity.

- Exceptional Hardness and Lifespan: Precisely ground to a hardness of 60 degrees, our Terminal machine blade/OTP blade achieves a remarkable lifespan of over 50 million crimping cycles, significantly reducing replacement frequency and downtime.

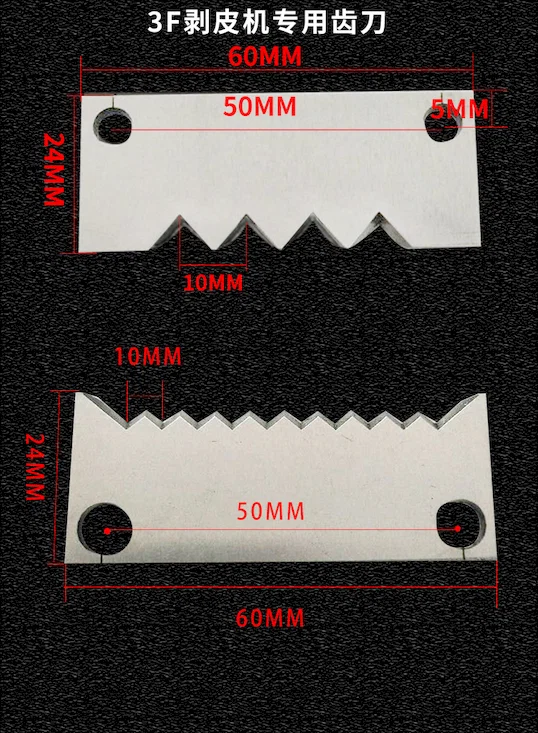

- Custom-Designed to Terminal Specifications: Each Crimping Knife and die is meticulously designed and manufactured according to specific terminal specifications, ensuring perfect compatibility and optimal crimping results every time.

- Model-Specific Mold Design: We design and produce molds tailored to specific crimp machine models, guaranteeing seamless integration and peak performance with your existing equipment.

- Cost-Effective Bulk Pricing: Benefit from significant cost savings with larger quantity orders. Our competitive pricing makes high-quality Wire Strip And Crimp Machine Dies accessible without compromising on performance.

- Advanced Manufacturing and Expert Engineering: Backed by sophisticated production equipment and a robust technical team, we are a technology-driven enterprise specializing in precision tool mold making, research, and development.

- Experienced and Skilled Professionals: Our company boasts a team of experienced and highly skilled professional and technical personnel, dedicated to producing the highest quality tooling.

- Custom Graphic Design and High Precision Manufacturing: We can design a variety of custom graphics according to customer requirements and are capable of producing cutter molds that are high-precision, exceptionally durable, and designed for long life, meeting even the most demanding applications.

Technical Superiority for Unmatched Reliability:

- Material: Japan High-Quality DC53 Steel

- Hardness: 60 Degrees

- Lifespan: > 50 Million Crimping Cycles

- Processing: Vacuum Heat Treatment (Ten Times Processed)

- Customization: Terminal Specifications, Crimp Machine Model Types

Conclusion:

Invest in our premium Terminal machine blade/OTP blade solutions and experience a significant improvement in the reliability and efficiency of your wire crimping operations. Stop wasting time and money on inferior blades. Our Wire Strip And Crimp Machine Dies and Crimping Knife offerings deliver unmatched durability, precision, and longevity. Contact us today to learn more about how our superior tooling can transform your production and reduce your operational costs!

Reviews

There are no reviews yet.